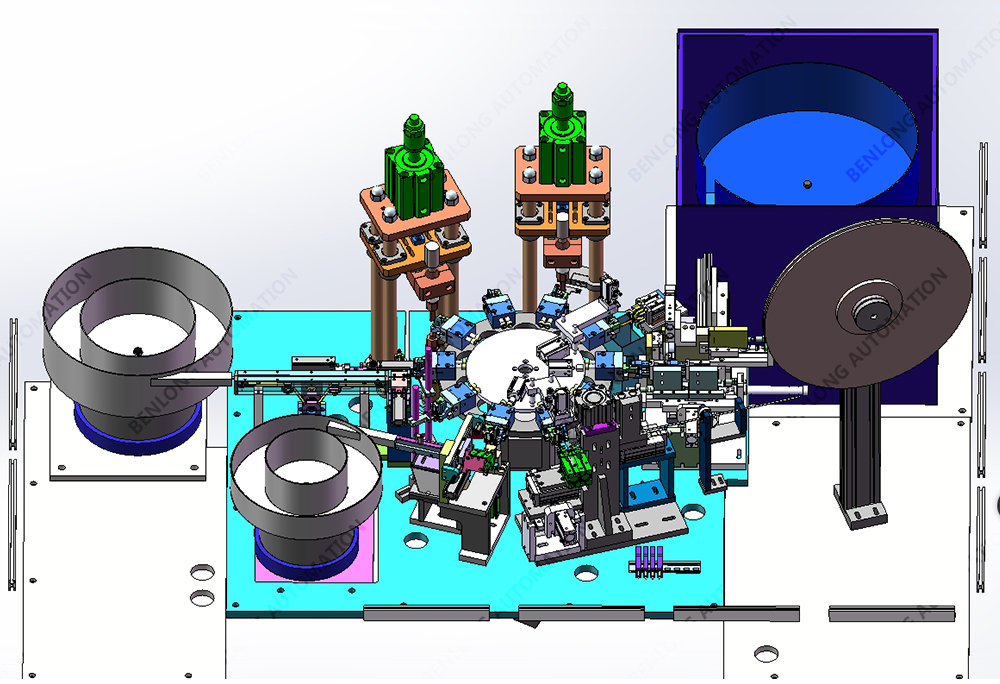

Inkqubo yokukhutshwa kwe-MCB yombane we-electromagnetic enkulu yesibiyeli isixhobo sokuwelda esizenzekelayo

Bona Okunye>>Ukusebenza kakuhle:

Izixhobo ze-welding ezizenzekelayoinokuphucula kakhulu ukusebenza kakuhle kwemveliso ngokunciphisa ukungenelela ngesandla kunye nexesha lokulinda ngokusebenzisa imisebenzi ye-welding eqhubekayo.

Isantya se-welding sidla ngokukhawuleza kwaye sinokugqiba inani elikhulu lomsebenzi we-bracket welding ngexesha elifutshane.

Ukuchaneka:

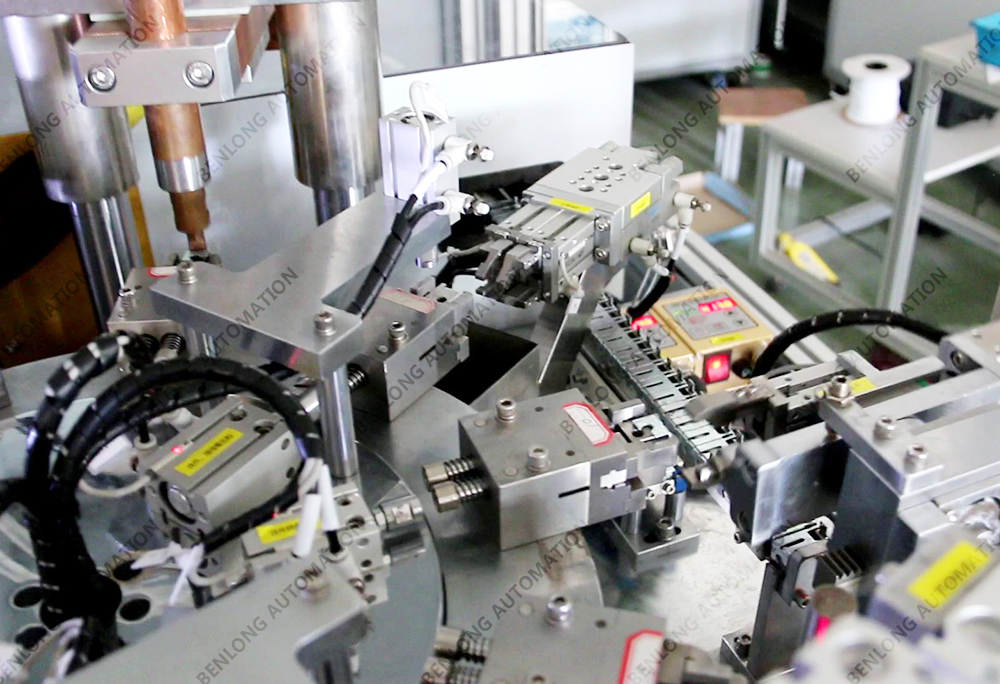

Izixhobo ze-welding ezizenzekelayo zihlala zisebenzisa iinkqubo zokulawula ezichanekileyo zokuqinisekisa ukuchaneka kwezikhundla ze-welding.

Ngokusebenzisa iiparamitha ze-welding ezicwangcisiweyo kunye neenkqubo, ulawulo oluchanekileyo lwenkqubo ye-welding inokufezekiswa, ukuqinisekisa ukuhambelana kunye nokuzinza komgangatho we-welding.

Ukuthembeka:

Izixhobo ze-welding ezizenzekelayo zihlala zithatha iteknoloji ye-welding ephezulu kunye nezixhobo, ezinokuthembeka okuphezulu kunye nokuqina.

Isixhobo sinokusebenza ngokuzinzileyo ixesha elide, ukunciphisa ukungaphumeleli kunye nexesha lokuphumla, kunye nokuphucula ukuthembeka okupheleleyo komgca wemveliso.

Ukuba bhetyebhetye:

Izixhobo zokuwelda ezizenzekelayo zihlala zineendlela ezininzi zokuwelda kunye noseto lweparameter, ezinokuqhelana neemfuno zewelding yeemodeli ezahlukeneyo kunye neenkcukacha.MCBinkqubo yokukhulula thermal izibiyeli ezinkulu.

Ngokuhlengahlengisa iiparamitha ze-welding kunye neenkqubo, kunokwenzeka ukuba uxhase ukuxhaswa kwezinto ezahlukeneyo kunye nobukhulu.

1. Isixhobo sombane wegalelo 380V ± 10%, 50Hz; ±1Hz

2. Isixhobo sinokuyilwa ukuba sihambelane nobukhulu obuninzi.

3. Ixesha lomjikelo wemveliso yezixhobo: ≤ 3 imizuzwana ngeqhekeza.

4. Isixhobo sinomsebenzi wohlalutyo oluzenzekelayo lwezibalo zedatha ye-OEE.

5. Xa utshintshe imveliso phakathi kweemveliso zenkcazo eyahlukeneyo, ukutshintshwa kwencwadana yokubumba okanye ukulungiswa kuyadingeka.

6. Ixesha le-Welding: 1 ~ 99S. Iiparamitha zingasetwa ngaphandle kwesizathu.

7. Isixhobo sinemisebenzi yokubonisa i-alamu efana ne-alarm yephutha kunye nokubeka iliso loxinzelelo.

8. Kukho iinkqubo ezimbini zokusebenza: uguqulelo lwesiTshayina kunye noguqulelo lwesiNgesi.

9. Onke amacandelo aphambili angeniswa kumazwe ahlukeneyo nakwimimandla efana ne-Itali, iSweden, iJamani, iJapan, iUnited States, neTaiwan.

10. Isixhobo sinokuxhotyiswa ngemisebenzi efana ne "Smart Energy Analysis and Energy Management System" kunye ne "Intelligent Equipment Service Big Data Cloud Platform".

11. Ukuba namalungelo azimeleyo kunye nobunini bepropathi enomgangatho ophezulu wokuqonda