System Features:

High efficiency: the equipment adopts automated welding process, which can quickly and efficiently complete the welding tasks of wires, temperature sensing pieces and terminal boards, and improve the production efficiency.

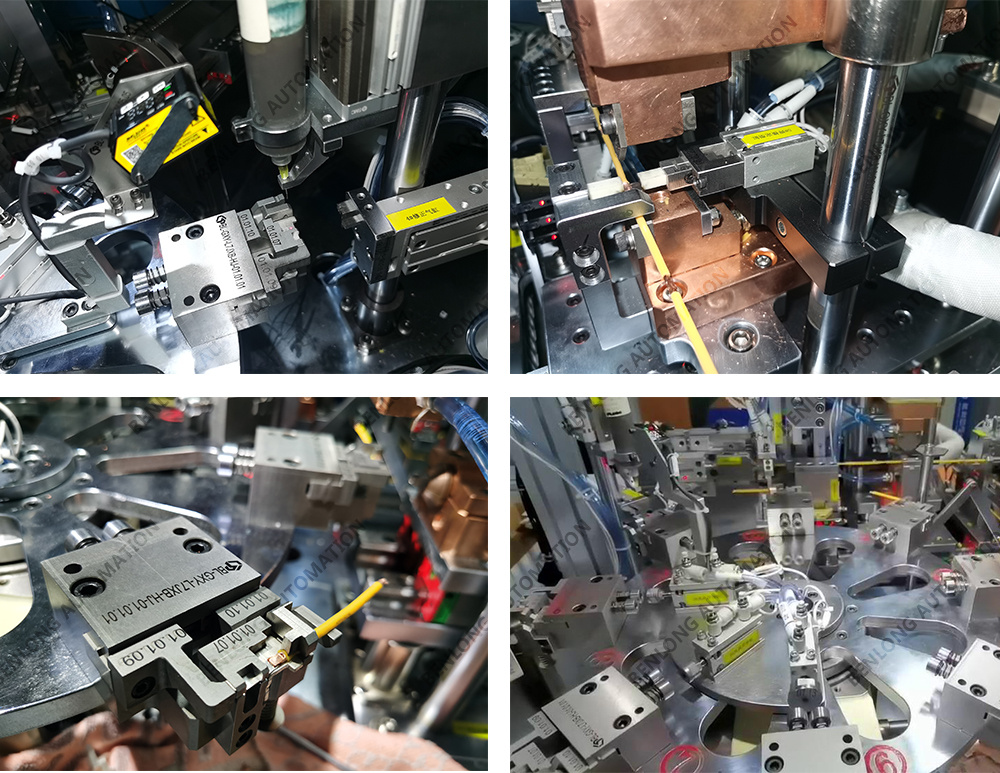

Accuracy: The equipment is equipped with high-precision welding head and control system, which can monitor and control the welding parameters in real time to ensure the accuracy and stability of welding quality.

Flexibility: The equipment adopts modularized design, which can be configured and adjusted according to different welding needs, and is suitable for welding tasks of a wide range of wires, temperature sensing pieces and terminal boards.

Reliability: The equipment adopts advanced control technology with stable power output and protection measures, which can operate stably for a long time and improve the reliability and service life of the equipment.

Product Features:

Automated Welding: The equipment is able to automatically complete the welding work of wires, temperature sensing pieces and terminal boards, improving production efficiency and consistency.

Welding quality control: The equipment is equipped with precise control system and sensors, which can monitor the welding quality in real time and detect whether the welding joints are firm, whether the resistance is qualified, etc. to ensure the welding quality.

Flexible welding modes: The equipment supports multiple welding modes, such as spot welding, continuous welding, intermittent welding, etc. It can be adjusted according to different welding needs and is suitable for welding of different materials and processes.

Data management: The equipment has data management function, which can record and store welding process parameters, welding results and other data, which is convenient for production process tracking and quality analysis.

Through the above system features and product functions, the automatic welding equipment for wires, temperature sensing pieces and terminal boards realizes the automation, high efficiency and precision of the welding process, improves the production efficiency and product quality, and provides users with stable and reliable welding solutions.