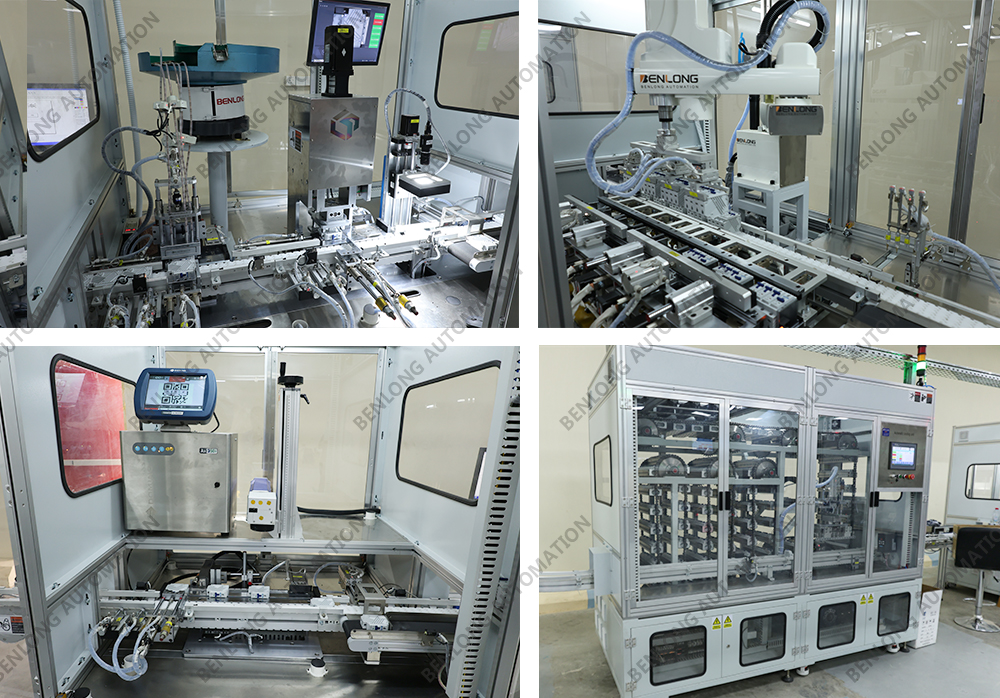

MCB garis produksi uji alat otomatis

Tempo deui >>The processes of the production line include: automatic assembly, automatic assembly, automatic coding, automatic nail threading, automatic riveting, automatic instantaneous, automatic time-delay, automatic cooling, automatic time-delay recalibration, automatic mechanical characteristics, automatic pass/fail, automatic pressure resistance, automatic pad-printing, automatic laser marking, automatic mounting of snap/stop parts, manual packing table, robotic palletising and loading and unloading, MES system data storage, SOP electronic display screen, etc., compatible with the production of 1P, 2P, 3P, 4P, B-type, C-type, D-type, 18-module or 27-module, etc., the production line has online testing, real - ngawaskeun waktos, traceability kualitas, barcode atanapi kode dua diménsi otomatis idéntifikasi jeung maca, ngawas kahirupan komponén, sistem jeung jaringan sistem ERP, parameter tina rumus sawenang, Analisis énergi calakan sarta sistem manajemen hemat energi, jasa parabot calakan, platform data badag sarta fungsi sejen, unggal mesin dijieun ku Benny. Fungsi, unggal mesin dirancang jeung dikembangkeun ku Penlong Automation mandiri, programming software, Anjeun bisa ngadalikeun operasi mesin ngaliwatan layar tampilan, éta boga kurangna alarem bahan, faults laporan, nyukcruk data produksi produk, data OEE, jeung sajabana kondusif pikeun produksi lean, ngungkulan, replenishment timely, jsb, sistem operasi ngarojong desain multi-basa. Bagian inti pakakas téh sadayana ti suppliers brand kawentar dunya kayaning Jerman, Italia, Jepang, Inggris, AS, jsb Ieu bisa mantuan pabrik anjeun ngahemat leuwih tanaga gawé jeung waktu, sadar automation pabrik jeung grab pangsa pasar leuwih pikeun anjeun.

1, Parabot tegangan input: 380V ± 10%, 50Hz; ± 1Hz;

2, cocog parabot: 1P, 2P, 3P, 4P, tipe B, tipe C, tipe D, 18 modulus atawa 27 modulus.

3, alat produksi ngéléhkeun: 1 detik / kutub, 1,5 detik / kutub, 2 detik / kutub, 2,4 detik / kutub, 3 detik / kutub, 5 detik / kutub genep pilihan.

4, produk pigura cangkang sarua, kutub béda bisa switched ku hiji konci atawa kode scanning; ngaganti produk pigura cangkang béda kudu sacara manual ngaganti kapang atawa fixture.

5, mode Majelis: assembly manual, assembly otomatis tiasa pilihan.

6, fixture Equipment bisa ngaropéa nurutkeun model produk.

7, Alat jeung alarem sesar, ngawas tekanan sarta fungsi tampilan alarem lianna.

8, versi Cina jeung Inggris tina dua sistem operasi.

9, Sadaya bagian inti anu diimpor ti nagara béda jeung wewengkon kayaning Italia, Swédia, Jérman, Jepang, Amérika Serikat, Taiwan jeung saterusna.

10, alat-alat nu bisa jadi pilihan "analisa énergi calakan sarta sistem manajemen hemat energi" jeung "jasa parabot calakan platform awan data badag" jeung fungsi séjén.

11. Hak cipta intelektual anu mandiri