Marang-rang a Lintho tse bohlale tse nyane tsa potoloho ea sekhechana sa ho phunya le lisebelisoa tsa riveting

Sheba Tse ling >>

1. Matla a ho kenya lisebelisoa: 220V / 380V ± 10%, 50Hz; ± 1Hz;

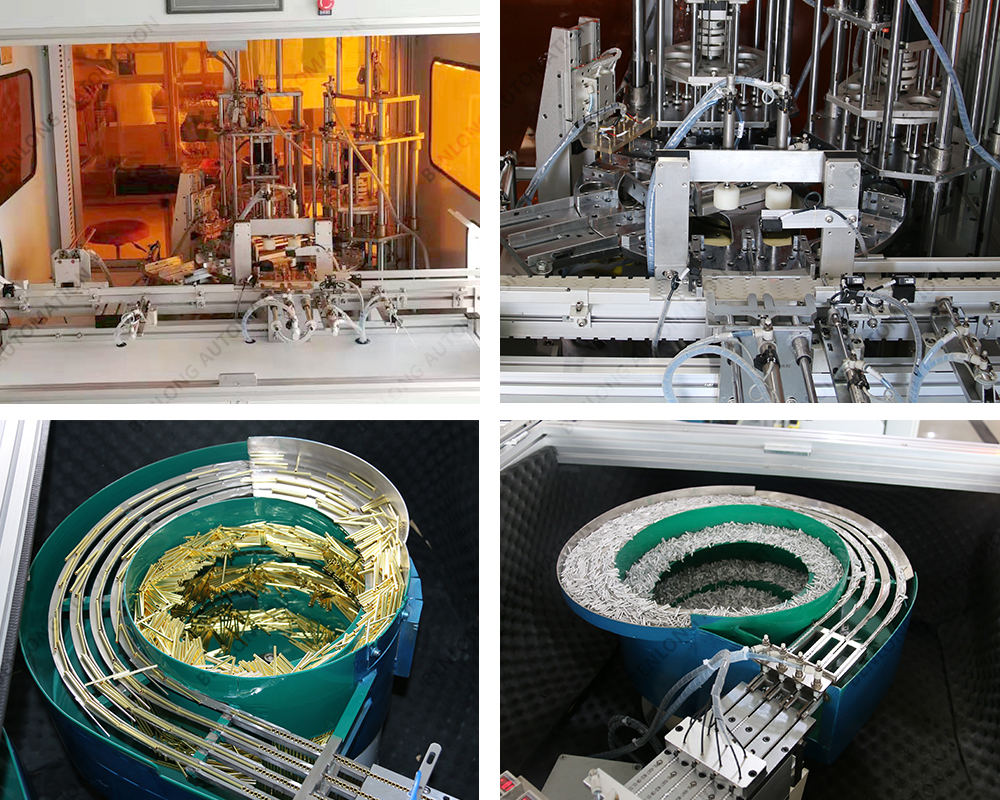

2. Lisebelisoa tse lumellanang le lisebelisoa: 1P + module, 2P + module, 3P + module, 4P + module.

3. Moribo oa tlhahiso ea lisebelisoa: ≤ metsotsoana ea 10 ka palo.

4. Sehlahisoa se tšoanang sa shelefo se ka fetoloa pakeng tsa lipalo tse fapaneng ka ho tobetsa ho le mong kapa ho fetola khoutu ea scan; Lihlahisoa tse fapaneng tsa likhetla tsa khetla li hloka ho khutlisa hlobo kapa lisebelisoa ka letsoho.

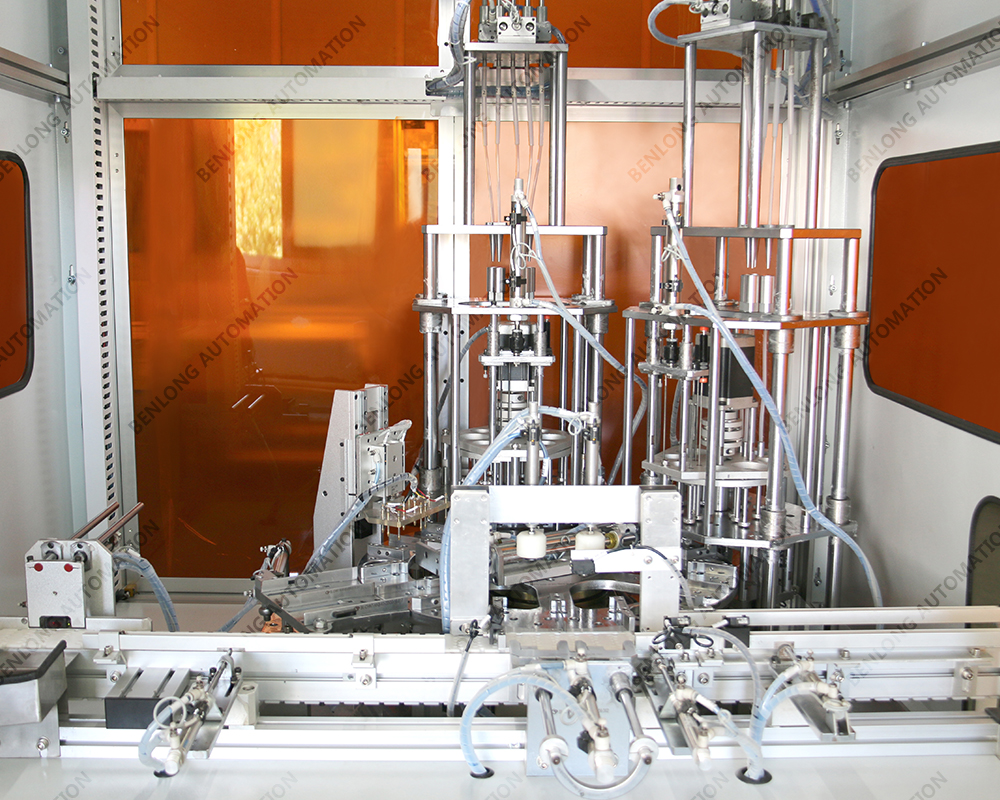

5. Mokhoa oa ho fepa li-rivet ke ho fepa ka li-vibration disc; Lerata ≤ 80 decibel; Palo ea li-rivets le hlobo e ka etsoa ho latela mohlala oa sehlahisoa.

6. Lebelo le likarolo tsa vacuum tsa mochine oa ho arola lipekere li ka behoa ka mokhoa o ikemetseng.

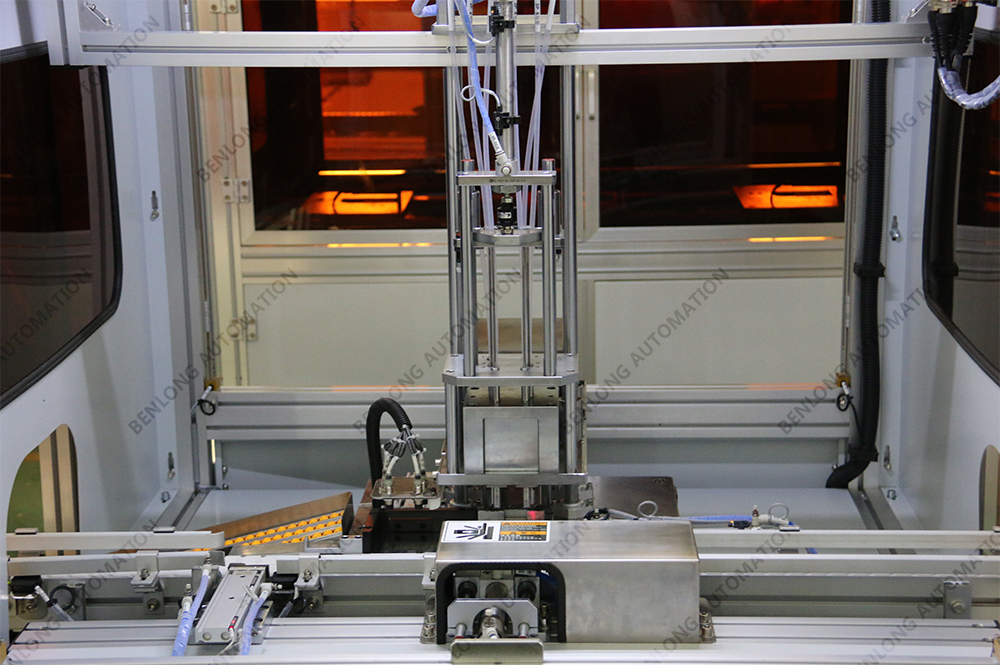

7. Ho na le likhetho tse peli bakeng sa riveting: cam riveting le servo riveting.

8. Li-parameter tsa lebelo la riveting li ka behoa ka mokhoa o ikemetseng.

9. Thepa e na le mesebetsi ea pontšo ea alamo e kang alamo ea phoso le tlhokomelo ea khatello.

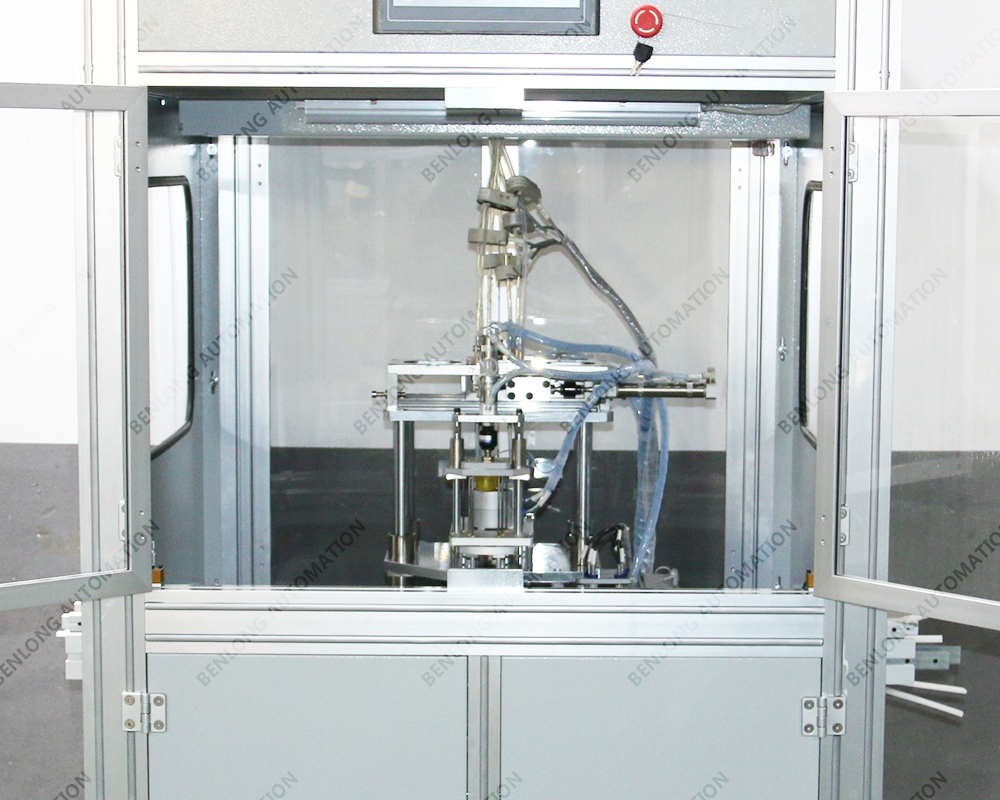

10. Ho na le litsamaiso tse peli tsa ts'ebetso tse fumanehang: Sechaena le Senyesemane.

11. Lisebelisoa tsohle tsa mantlha li romelloa ho tsoa linaheng tse fapaneng le libaka tse kang Italy, Sweden, Jeremane, Japane, United States, Taiwan, joalo-joalo.

12. Sesebelisoa se ka ba le lisebelisoa tse kang "Smart Energy Analysis le Energy Conservation System" le "Smart Equipment Service Big Data Cloud Platform".

13. Ho ba le litokelo tse ikemetseng le tse ikemetseng tsa thepa ea mahlale.