System Features:

Kunyanya kushanda zvakanaka: michina inotora otomatiki welding process, iyo inogona kukurumidza uye nemazvo kupedzisa mabasa ekushongedza waya, zvidimbu zvekunzwa tembiricha uye mabhodhi ekupedzisira, uye kuvandudza mashandiro ekugadzira.

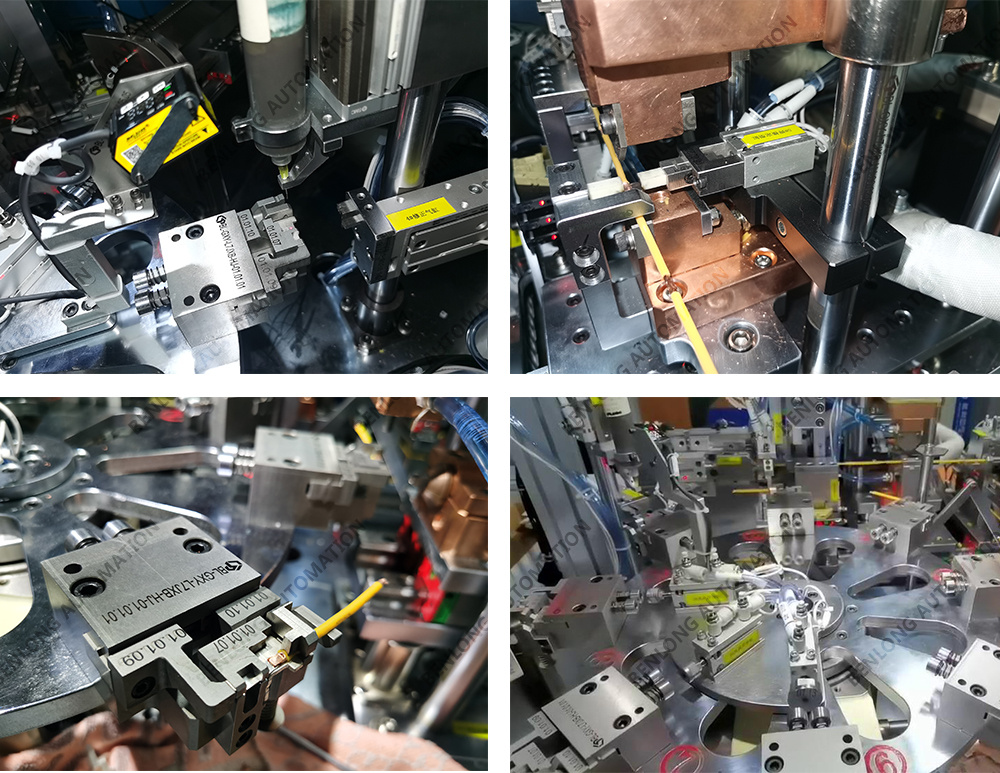

Kunyatsoita: Midziyo yacho yakashongedzerwa nepamusoro-chaiyo welding musoro uye control system, iyo inogona kutarisa uye kutonga iyo welding parameters munguva chaiyo kuti ive nechokwadi chechokwadi uye kugadzikana kwemhando yewelding.

Flexibility: Iyo midziyo inotora modularized dhizaini, iyo inogona kugadzirwa uye kugadziridzwa zvinoenderana neyakasiyana welding zvinodiwa, uye inokodzera welding mabasa emhando dzakasiyana dzewaya, tembiricha inonzwa zvidimbu uye terminal mabhodhi.

Kuvimbika: Midziyo inotora tekinoroji yekudzora tekinoroji ine simba rakagadzikana rekubuda uye matanho ekudzivirira, anogona kushanda akadzikama kwenguva yakareba uye anovandudza kuvimbika uye hupenyu hwebasa remidziyo.

Product Features:

Automated Welding: Midziyo yacho inokwanisa kuzadzisa otomatiki basa rekushongedza waya, zvidimbu zvekunzwa tembiricha uye mabhodhi ekupedzisira, kuvandudza kushanda kwekugadzira uye kuenderana.

Welding quality control: Midziyo yacho yakashongedzerwa neiyo chaiyo control system uye masensa, ayo anogona kutarisa welding mhando munguva chaiyo uye kuona kana majoini ewelding akasimba, kana kupikisa kwakakodzera, nezvimwewo kuve nechokwadi chemhando yewelding.

Flexible welding modes: Iyo midziyo inotsigira akawanda welding modes, senge nzvimbo welding, inoenderera welding, intermittent welding, etc. Inogona kugadziridzwa zvinoenderana neyakasiyana welding zvinodiwa uye inokodzera welding yezvinhu zvakasiyana uye maitiro.

Dhata manejimendi: Iyo midziyo ine data manejimendi basa, iyo inogona kurekodha uye kuchengeta welding process paramita, welding mhinduro uye imwe data, iri nyore pakugadzira maitiro ekutevera uye kuongororwa kwemhando.

Kuburikidza neari pamusoro pemaitiro ehurongwa uye mabasa echigadzirwa, otomatiki welding midziyo yewaya, tembiricha inonzwa zvidimbu uye terminal mabhodhi anoona otomatiki, hunyanzvi hwepamusoro uye nemazvo ekugadzira welding, inovandudza kugadzirwa kwemhando uye mhando yechigadzirwa, uye inopa vashandisi yakagadzikana uye yakavimbika. welding mhinduro.