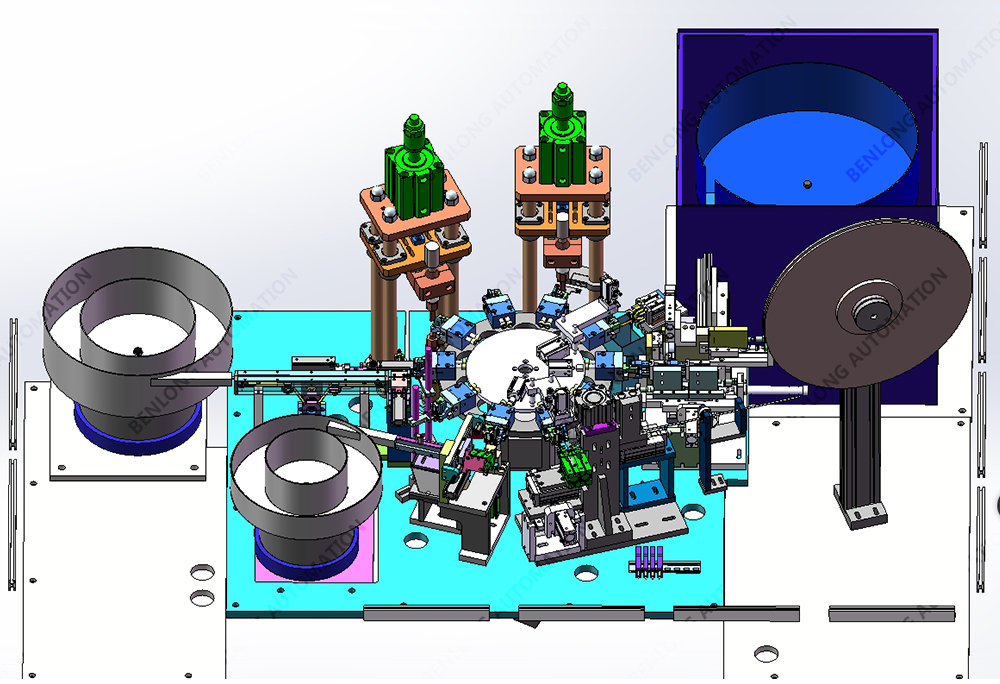

MCB electromagnetic component thermal release system hombe bracket otomatiki welding michina

Ona Zvakawanda>>Kubudirira:

Automatic welding equipmentinogona kuvandudza zvakanyanya kugadzirwa kwekugadzira nekudzikisa kupindira kwemanyore uye nguva yekumirira kuburikidza nekuenderera mberi welding mashandiro.

Iko kumhanya kwewelding kunowanzo kukurumidza uye inogona kupedzisa nhamba yakakura yebasa remabhureki welding munguva pfupi.

Kururama:

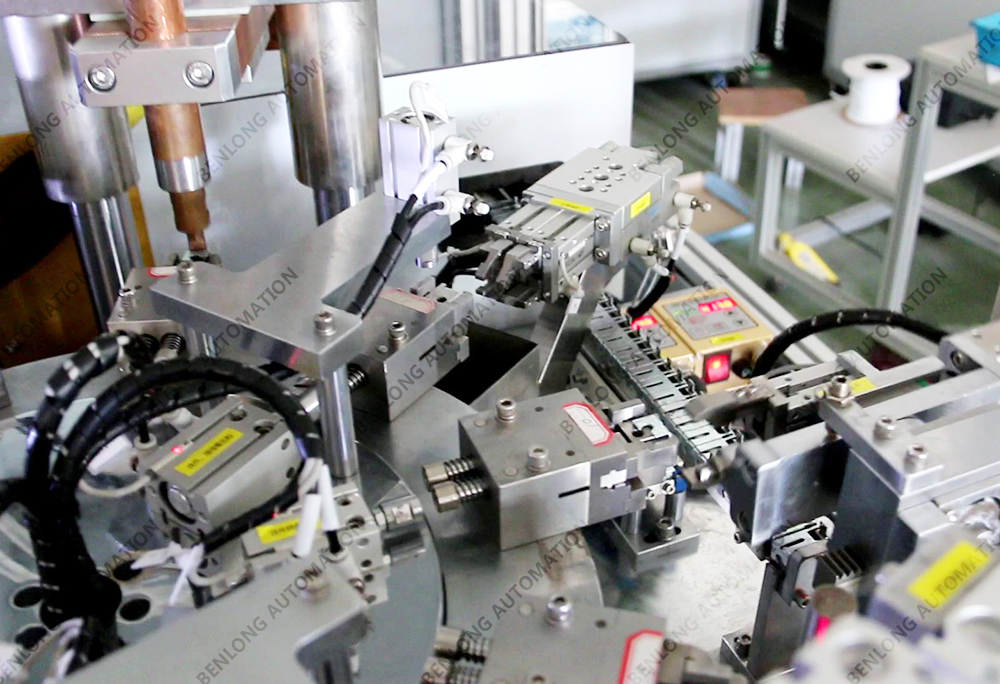

Otomatiki welding midziyo inowanzo shandisa yakakwirira-chaiyo kudzora masisitimu kuti ive nechokwadi chechokwadi chezvinzvimbo zvewelding.

Kuburikidza nepreset welding paramita uye zvirongwa, kunyatso kudzora kweiyo welding process inogona kuwanikwa, kuve nechokwadi chekuenderana uye kugadzikana kwemhando yewelding.

Kuvimbika:

Otomatiki welding midziyo inowanzo tora advanced welding tekinoroji uye zvinhu, zvine kuvimbika kwakanyanya uye kusimba.

Midziyo inogona kushanda yakadzikama kwenguva yakareba, kuderedza kutadza uye kuderera, uye kugadzirisa kuvimbika kwese kwemutsara wekugadzira.

Kuchinjika:

Otomatiki welding midziyo inowanzo ine akawanda welding modes uye parameter marongero, ayo anogona kuenderana kune welding zvinodiwa zvemhando dzakasiyana uye zvakatemwa zve.MCBthermal release system mabhuraketi makuru.

Nekugadzirisa welding parameters uye maitiro, zvinokwanisika kusungira zvitsigiso zvezvinhu zvakasiyana uye ukobvu.

1. Equipment input voltage 380V ± 10%, 50Hz; ±1Hz;

2. Chigadzirwa chacho chinogona kugadzirwa kuti chienderane nehukuru hwakawanda.

3. Equipment production cycle time: ≤ 3 seconds per piece.

4. Iyo midziyo ine basa re otomatiki nhamba yekuongorora yeOEE data.

5. Paunenge uchishandura kugadzirwa pakati pezvigadzirwa zvemhando dzakasiyana-siyana, kushandiswa kwebhuku rekugadzira molds kana zvigadziro zvinodiwa.

6. Welding nguva: 1 ~ 99S. Parameters inogona kusetwa zvisina tsarukano.

7. Iyo midziyo ine aramu kuratidza mabasa akadai senge fault alarm uye pressure monitoring.

8. Pane maitiro maviri ekushanda: Chinese version uye Chirungu version.

9. Zvose zvikamu zvakakosha zvinotengeswa kubva kunyika dzakasiyana-siyana uye nzvimbo dzakadai seItaly, Sweden, Germany, Japan, United States, neTaiwan.

10. Chigadzirwa chacho chinogona kugadzirirwa mabasa akadai se "Smart Energy Analysis uye Energy Management System" uye "Intelligent Equipment Service Big Data Cloud Platform".

11. Kuve nekodzero dzakazvimirira uye dzevaridzi vepfuma yeruzivo