System features:

Kunyanya kushanda zvakanaka: Iyo michina inotora otomatiki maitiro, ayo anogona kupedzisa basa rewelding ye bimetal sheet uye kufambisa macontact uye mhangura yakarukwa waya munguva pfupi, kuvandudza kushanda zvakanaka.

Kunyatsoita: Midziyo yacho yakashongedzerwa nepamusoro-chaiyo sensors uye kudzora masisitimu, ayo anogona kunyatso kudzora tembiricha, kudzvanywa uye nguva panguva yekugadzira welding kuti ive nechokwadi chekugadzikana kwehudhiro.

Kugadzikana: Kushandisa tekinoroji yepamusoro yekudzora, midziyo ine kugadzikana kwakanaka uye kupesana-kupindira kugona, inogona kumhanya yakadzikama kwenguva yakareba, kuderedza kutadza uye kuderera.

Kuvimbika: Midziyo inogadzirwa neyemhando yepamusoro zvinhu uye zvikamu, zvine kusimba kwepamusoro uye kuvimbika, uye inogona kuenderana neakasiyana nharaunda dzekushanda.

Zviri nyore kushanda: Midziyo yacho ine intuitive operation interface uye mushandisi-inoshamwaridzika control system, iri nyore kushanda, kuderedza kuoma kwekushanda.

Product features:

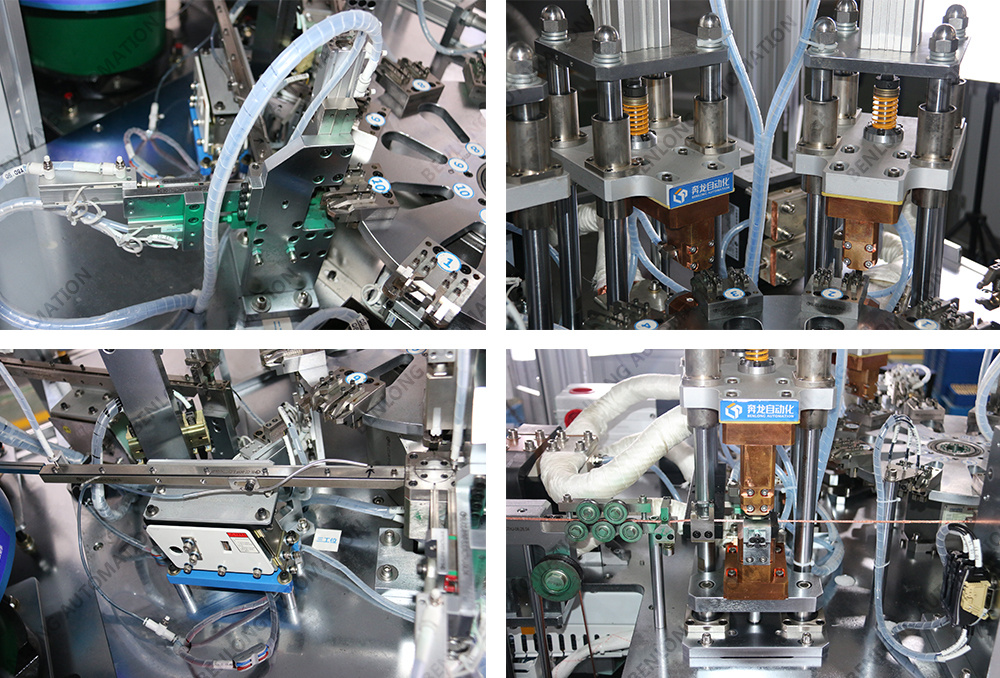

Bimetal sheet welding: Iyo midziyo inogona kukurumidza uye nenzira kwayo kupinza bimetal sheets kuti ive nechokwadi chekuti welding point yakasimba uye yakagadzikana.

Moving contact welding: Midziyo yacho inogona kunyatso shongedza iyo inofamba yekubata kuti ive nechokwadi chekuti welding mhando inosangana nezvinodiwa.

Mhangura yakarukwa waya welding: Midziyo yacho inogona kunyatso kupedzisa basa rekushongedza remhangura yakarukwa waya kuti ive nechokwadi chekuvimbika kwemhando.

Kudzora otomatiki: Midziyo yacho ine otomatiki yekudzora sisitimu, iyo inogona kuona otomatiki yekutarisa uye kutonga kweiyo welding maitiro, kunatsiridza kugadzirwa kwakanaka uye kugadzikana kwemhando.

Kurekodha data uye kuongorora: Midziyo inogona kurekodha akakosha maparamita eiyo welding process, uye kuita ongororo yedata uye manhamba kuti ipe referensi yekutonga kwekugadzira uye manejimendi emhando.

Kuburikidza neari pamusoro pemaitiro ehurongwa uye mabasa echigadzirwa, bimetal plate + inofambisa macontact + yemhangura yakarukwa waya otomatiki welding michina inogona kusangana nezvinodiwa zvemaindasitiri ane hukama ewelding, kunatsiridza kugadzirwa kwakanaka uye kunaka kwechigadzirwa, uye kupa vashandisi mhinduro yakazara yewelding.