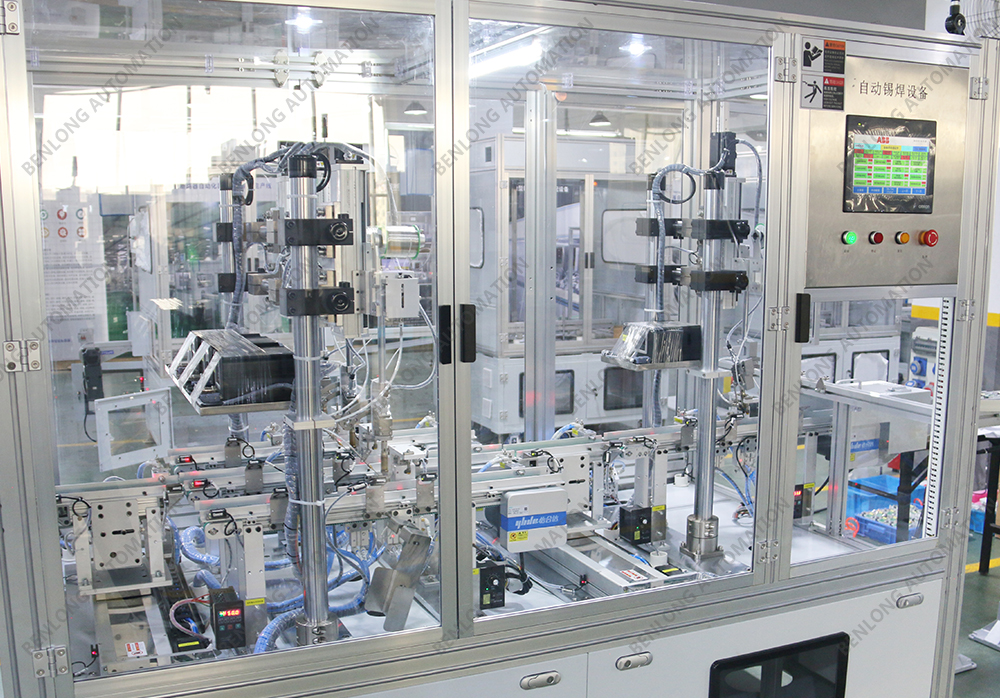

RCBO Leakage Circuit Breaker Automatic Soldering Equipment

See More>>With automatic assembly, filling welding auxiliary materials, testing, welding, soldering, defective product distinction, packaging, palletising, AGV logistics, lack of material

alarm and other processes of assembly, on-line testing, welding, real-time monitoring, quality traceability, barcode identification, component life monitoring, data storage,

MES system and ERP system networking, parameter arbitrary formula, intelligent energy analysis and energy-saving management system, smart equipment Service big data

cloud platform and other functions.

1、Equipment input voltage 380V±10%, 50Hz; ±1Hz;

2, equipment compatibility and production beat: can be customised according to customer requirements.

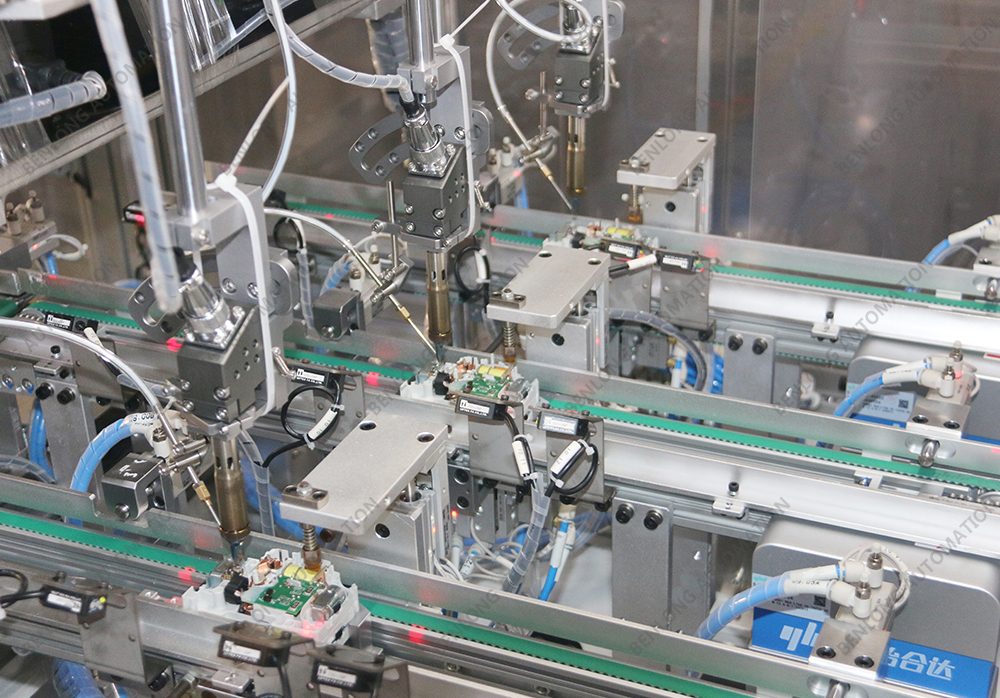

3、Welding method: according to the different production process and requirements of the product, it can be realised by resistance welding, medium-frequency welding,

high-frequency induction welding, laser welding, gas-shielded welding, tin soldering, friction welding, ultrasonic welding and so on.

4、Welding process: manual assembly automatic welding or automatic assembly automatic welding two modes can be optional.

5、Equipment fixture can be customised according to the product model.

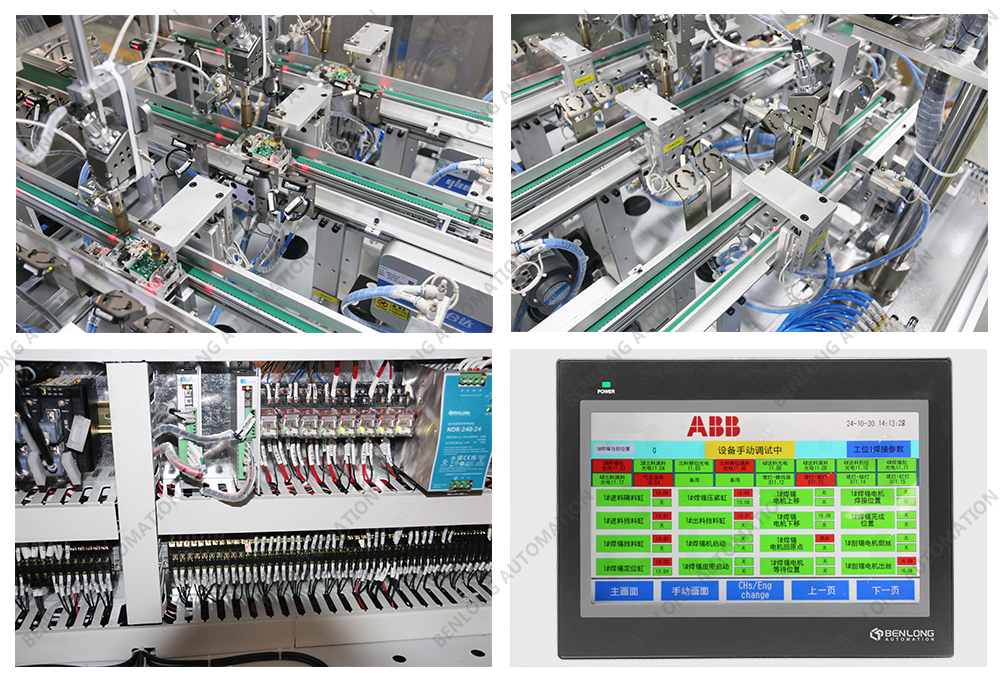

6、Equipment with fault alarm, pressure monitoring and other alarm display function.

7, Chinese version and English version of the two operating systems.

8、All core parts are imported from Italy, Sweden, Germany, Japan, the United States, Taiwan and other countries and regions.

9、Equipment can be equipped with optional functions such as ‘Intelligent Energy Analysis and Energy Saving Management System’ and ‘Intelligent Equipment Service Big Data Cloud Platform’.

10、It has independent independent intellectual property rights.

1、Equipment input voltage 380V±10%, 50Hz; ±1Hz;

2, equipment compatibility and production beat: can be customised according to customer requirements.

3、Welding method: according to the different production process and requirements of the product, it can be realised by resistance welding, medium-frequency welding, high-frequency induction welding, laser welding, gas-shielded welding, tin soldering, friction welding, ultrasonic welding and so on.

4、Welding process: manual assembly automatic welding or automatic assembly automatic welding two modes can be optional.

5、Equipment fixture can be customised according to the product model.

6、Equipment with fault alarm, pressure monitoring and other alarm display function.

7, Chinese version and English version of the two operating systems.

8、All core parts are imported from Italy, Sweden, Germany, Japan, the United States, Taiwan and other countries and regions.

9、Equipment can be equipped with optional functions such as ‘Intelligent Energy Analysis and Energy Saving Management System’ and ‘Intelligent Equipment Service Big Data Cloud Platform’.

10、It has independent independent intellectual property rights.

4mk_ldzsBDY