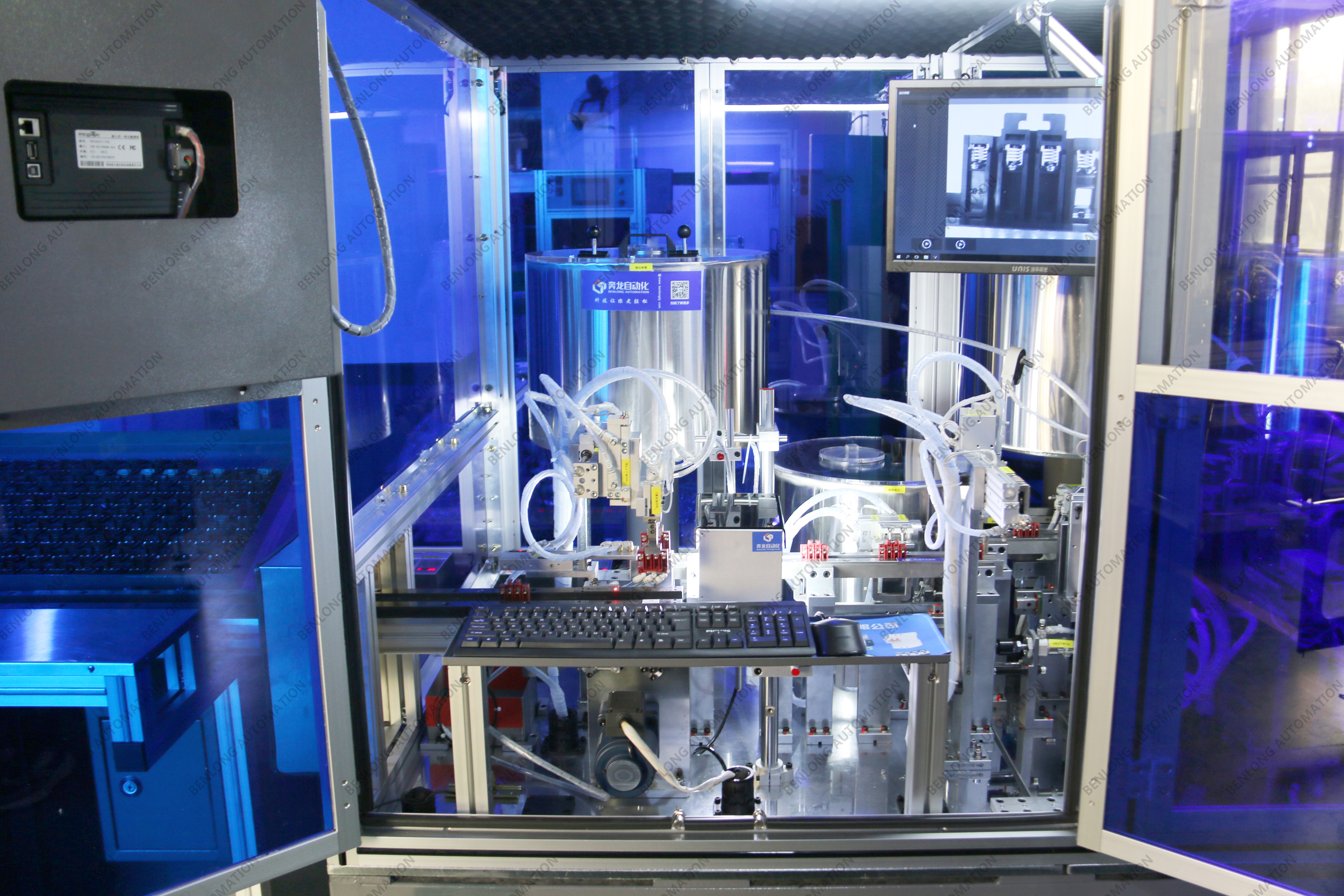

This automatic inserting machine is a high efficiency machine designed for DELIXI AC contactor production line, aiming to improve production efficiency and product quality. Through automated operation, the machine is able to realize efficient automation of the insertion process in the contactor manufacturing process, avoiding the errors and wasted man-hours of traditional manual operation. Its core functions include precise insertion positioning, fast insertion and pressure detection to ensure that each contactor insertion process meets the standard requirements.

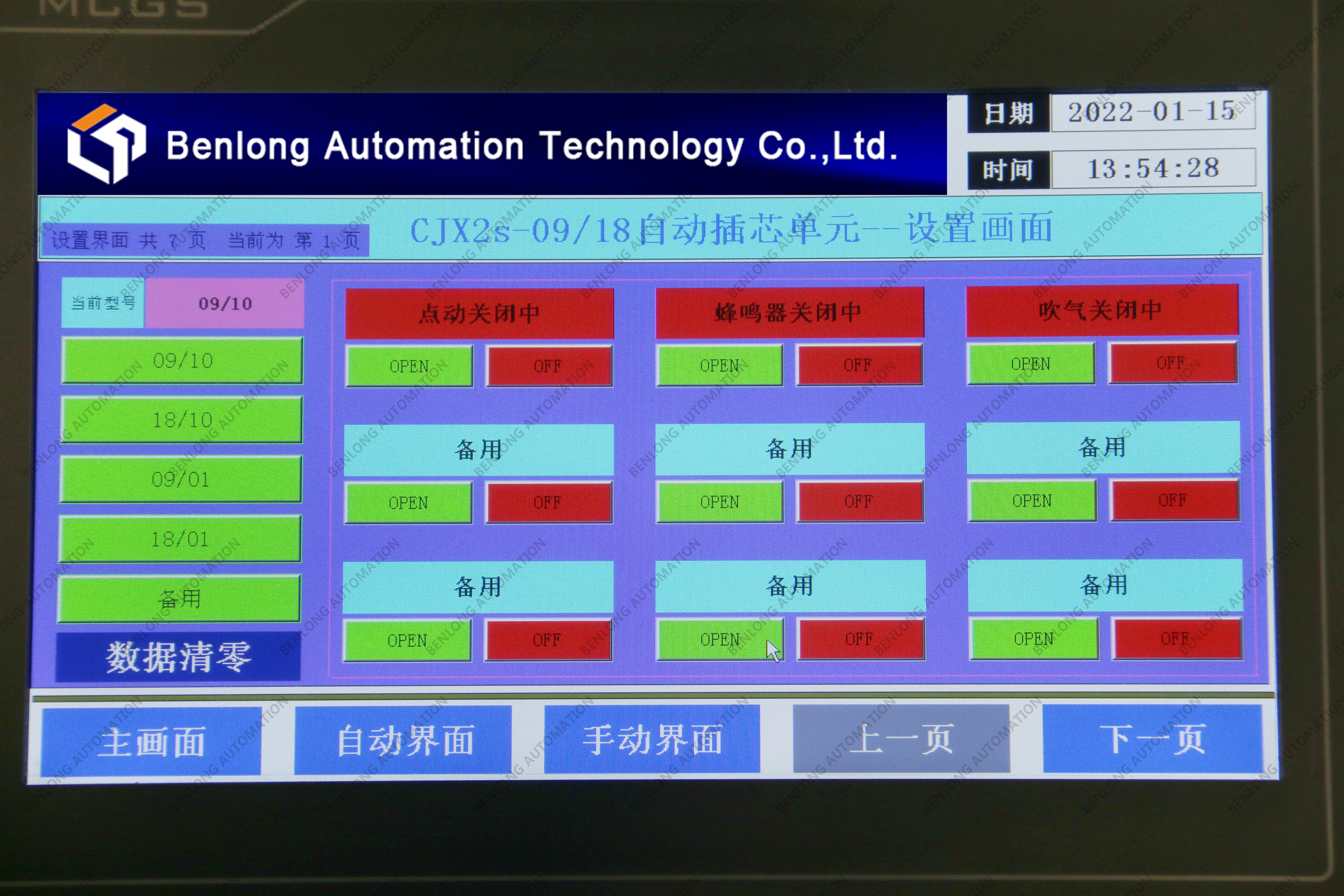

The equipment adopts advanced servo motor control system, combined with high-precision sensors, to ensure the accuracy of the insertion position and maximize production stability. The operation interface is simple and intuitive, and supports automatic switching of multiple contactor models, which greatly enhances the flexibility and adaptability of the production line. The machine is also equipped with an automated fault detection and alarm system, which monitors the machine’s operating status in real time to ensure the smooth running of the production process.

In addition, the design of the automatic inserting machine focuses on energy saving and environmental protection, adopting low power consumption technology, effectively reducing the running cost of the equipment. Through optimized design, it is able to maintain high efficiency in long-time continuous operation, which meets DELIXI’s needs in mass production.

Overall, this automatic inserting machine is an important part of DELIXI’s AC contactor production. Through automation and intelligence, it improves the production efficiency, reduces the risk of human operation, and ensures the stable quality of contactor products.

Post time: Nov-23-2024