https://www.youtube.com/watch?v=KMVq3x6uSWg

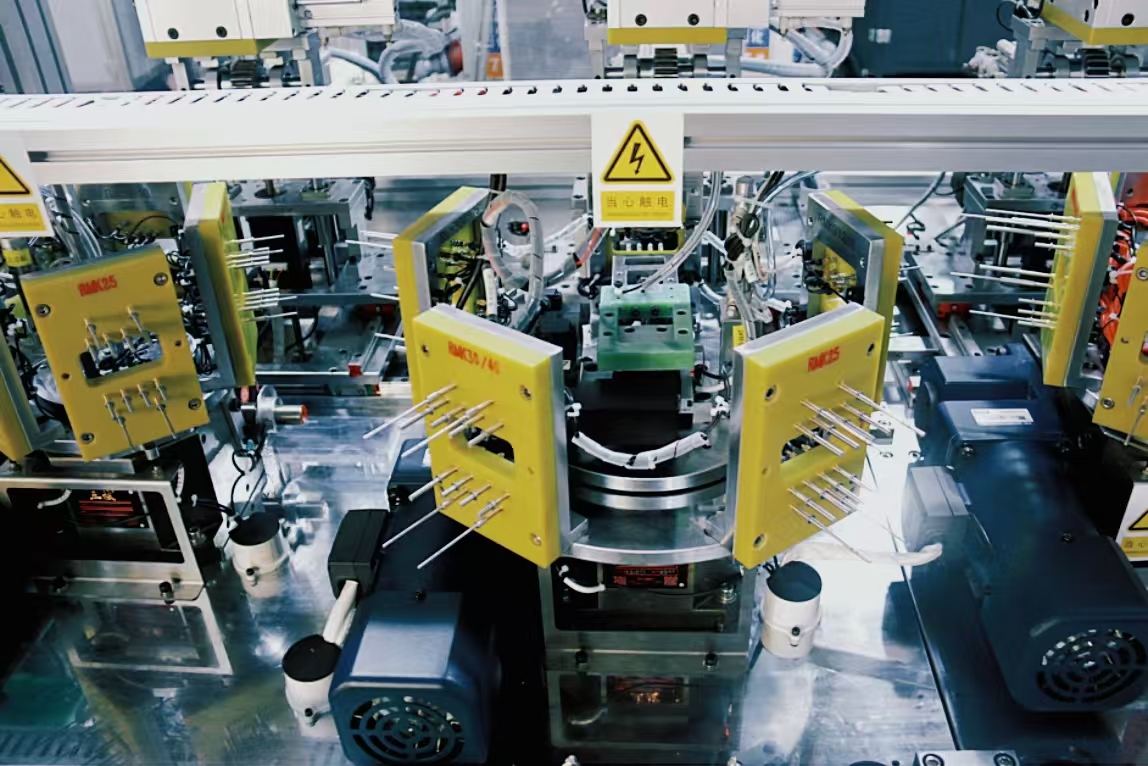

AC contactor automatic comprehensive test equipment, including the following five kinds of test content:

a) Contact contact reliability (on-off 5 times): Add 100% rated voltage to both ends of the coil of the AC contactor product, carry out on-off action 5 times (the parameters can be set arbitrarily) to detect whether the contacts of the product are reliably contacted, and it can directly display the on-off test condition of the contacts of each pole.

b) Suction/release voltage/holding power consumption:

i.Suction voltage test: according to the value of control voltage specification, the regulator raises the control voltage at a certain voltage at a constant speed until the product is suctioned, records the voltage value at this time that is the suction voltage, and determines whether the product is reliably suctioned or not; and then adjusts the control voltage to the rated voltage value to measure the power consumption of the coil, and compares all the measured values with the standard value to confirm whether it is qualified or not;

ii. Release voltage test: according to the control voltage specification value, the system first loads 100%Us on the coil (the voltage value can be set), lets the product act several times (the number of times can be set), and then reduces the control voltage at a uniform speed until the product is released, and records the voltage value at this time as the release voltage.

c) contact parameters: coil is not energized, the servo motor drives the probe mechanism movement in place (with the dynamic contact bracket contact), the probe mechanism action to determine the open distance reference zero position, compression of the dynamic contact until the static and dynamic contact contact contact, at this time, the probe mechanism movement distance that is, the open distance of the product; coil 100% Us energized suction, the servo motor drives the probe mechanism continues to move to contact with the dynamic contact bracket, to determine the overtraveling base zero position After the coil 100%Us is energized and absorbed, the servo motor drives the probe mechanism to continue moving to contact with the movable contact bracket to determine the overtravel reference zero position, and then the product is discharged by the power-off, the servo motor backs up, and the distance between zero position and disconnection with the movable and static contacts is the overtravel; the sum of the open distance and overtravel is the total travel. Each main contact open distance maximum and minimum value is subtracted to get the synchronization value. Comparison of the data with the set value, to determine qualified or not.

d) Voltage withstand: In the case of the coil is not energized, pressurized for 1 second, 2500VAC (voltage 0 ~ 5000V adjustable, leakage current 0 ~ 100mA adjustable) to test the incoming and outgoing terminals, the phase and the coil with the voltage characteristics of the coil; coil suction, the test phase with the ground, the coil with the ground with the characteristics of the withstand voltage.

This equipment can be compatible with five different sizes of AC contactors, is a very cost-effective machine.

Post time: Sep-09-2024