Improve production efficiency: The automated production line adopts advanced automated equipment and robots, which can realise high-speed and continuous production and greatly improve production efficiency.

Reduce cost: automated production line reduces manpower cost, and at the same time, it can reduce production cost by optimising the production process and reducing the scrap rate.

Enhance product quality: automated production line can achieve accurate production and efficient quality control to ensure stable and reliable product quality.

Flexibility to adapt to market demand: automated production line has a certain degree of flexibility, and can quickly adjust the production rhythm and output to adapt to changes in market demand.

High safety: the automated production line adopts advanced safety control system, which can reduce the safety risk in the production process and guarantee the safety of employees.

Data management: the automated production line collects the data in the production process, realises the data management and analysis of the production process, and provides the basis for production optimization and quality improvement.

Taken together, the AC contactor automated production line can improve production efficiency, reduce costs, improve product quality, while featuring high flexibility and safety, which is an important development direction for modern manufacturing industry.

Equipment system features:

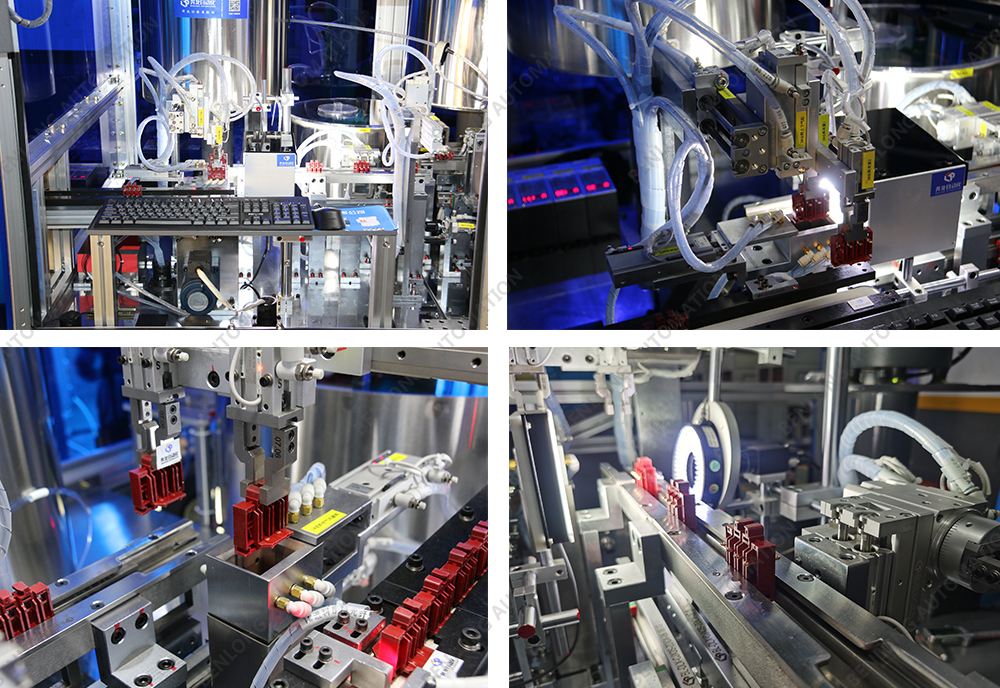

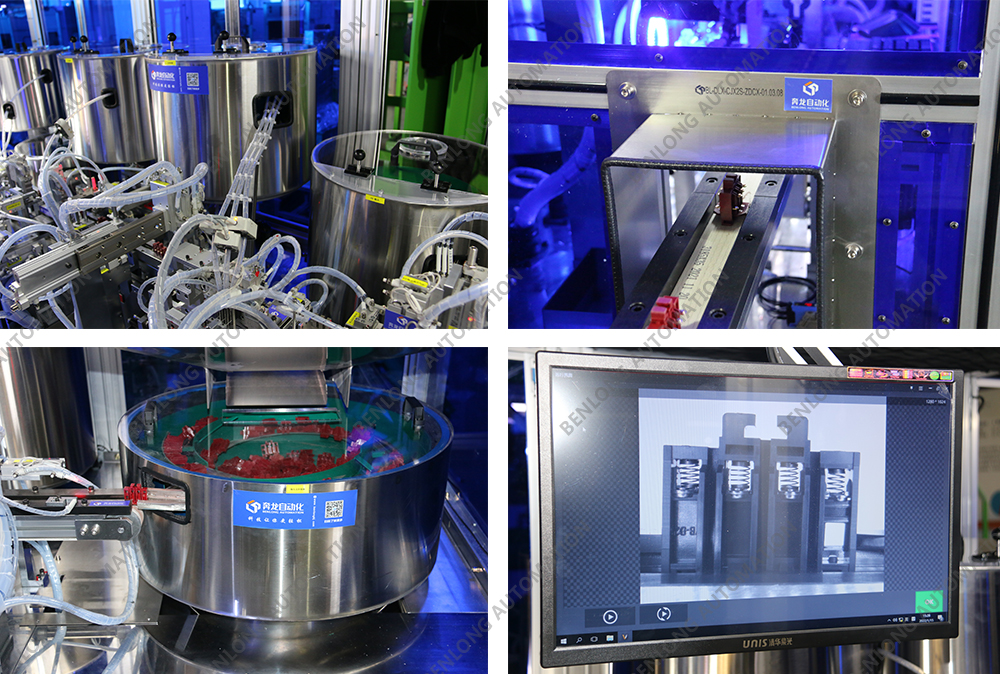

Adopting multi-specification mixed production, automation, informatisation, modularisation, flexibilisation, customisation, visualisation, cloud computing, one-key switching, early warning notification, assessment report, data collection and processing, global inspection management,

Equipment full life cycle management, more advanced, more intelligent, more reliable, highly integrated, intelligent scheduling, remote maintenance design concept.

Equipment Function:

With automatic loading, insert assembly, base assembly, main and auxiliary static contact assembly, manual assembly of pagoda spring, locking upper and lower cover screws, locking tile screws, through and through, pressure resistance, power consumption, forward tilt suction, backward tilt release, open distance, over-travelling, total travel, synchronicity, manual assembly of front and rear stops, pad printing, laser marking, CCD visual inspection, labelling, coding, bagging, bag-cutting, heat-shrinking, packaging, sealing, bundling, Palletising, AGV logistics, lack of material/full material alarm and other processes of assembly, online inspection, real-time monitoring, quality traceability, barcode identification, key components life monitoring, data storage, MES system and ERP system networking, parameter arbitrary recipe, intelligent energy analysis and energy-saving management system, intelligent equipment service big data cloud platform and other functions.

1. Equipment input voltage 380V ± 10%, 50Hz; ± 1Hz

2. Equipment compatibility specifications: CJX2-0901, 0910, 1201, 1210, 1801, 1810.

3. Equipment production rhythm: either 5 seconds per unit or 12 seconds per unit can be optionally matched.

4. Different specifications of products can be switched with just one click or by scanning the code; Switching between different shell products requires manual replacement or adjustment of molds/fixtures, as well as manual replacement/adjustment of different product accessories.

5. Assembly methods: manual assembly and automatic assembly can be freely selected.

6. The equipment fixtures can be customized according to the product model.

7. The equipment has alarm display functions such as fault alarm and pressure monitoring.

8. There are two operating systems available: Chinese and English.

9. All core accessories are imported from different countries and regions such as Italy, Sweden, Germany, Japan, the United States, and Taiwan.

10. The equipment can be optionally equipped with functions such as the Smart Energy Analysis and Energy Conservation Management System and the Smart Equipment Service Big Data Cloud Platform.

11. Having independent independent intellectual property rights.

Benlong Automation Technology Co., Ltd. was founded in 2008. We are a company specializing in the research and development, production, manufacturing, and sales of automation equipment in the power industry. We have mature production line cases, such as MCB, MCCB, RCBO, RCCB, RCD, ACB, VCB, AC, SPD, SSR, ATS, EV, DC, GW, DB, and other one-stop services; System integration technology services, complete equipment and software development, product design, and a comprehensive pre-sales and after-sales service system.

Post time: May-07-2024