Dear factory operators, are you often faced with a mirage of production problems: inconsistent quality, declining efficiency, high costs, tricky returns and complaints, like footprints on the beach that wash away once and then appear again the next day?

I know, you probably feel like you’re in a never-ending “TO DO list” vortex. Don’t worry, this is what I’m going to leave you with today, the second half of 2024, the work plan of the Department of Production Management, let’s work together to the peak of the production management of stubborn!

First of all, let’s take a look at the production line together, whether there are often products returned due to quality problems? Is the production process chaotic and inefficient? Is the cost high, so that the profit is damaged?

You need to review the current situation, sort out the difficulties and identify the actual problems. Remember, identifying the problems is the first step to solving them, so start by writing them down in a small notebook.

Then, you need to have a clear goal. Yes, in 2024, we can no longer “put out fires”, we need to have a clear goal.

MCB,MCCB,RCCB,RCBO,ACB,ATS, EV, DC,AC, DB, SPD,VCB

How much do you want to improve productivity? How much do you want to reduce product quality problems? Within what cost? Give yourself a quantifiable goal, write it on the production line in a conspicuous place, so that everyone can see.

Once the goal is set, the next step is to take action. How to act? Let me give you some directions.

First, focus on your employees and provide them with the training and education necessary to understand the importance of each job;

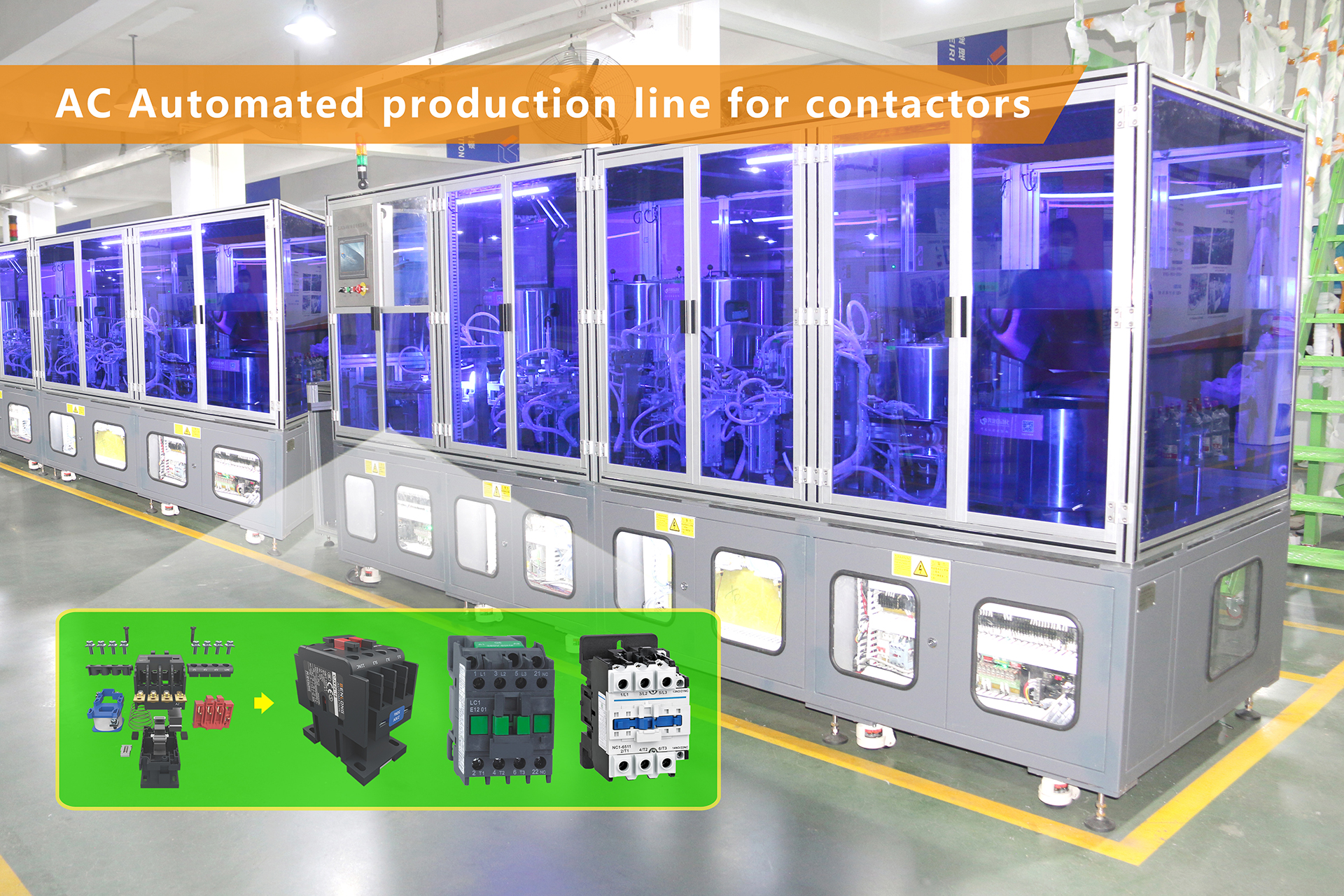

Second, evaluate and introduce automation equipment to see which parts of the process can be left to machines;

Third, setting up clear processes so that everyone understands their job responsibilities;

Fourthly, provide appropriate tools to make their work more manageable.

After all the theory, let me tell you a real example. There is an industrial park in a factory named ABC, their production line was originally full of problems and inefficiency.

Then they started to implement a new production management strategy. They provided professional training to their employees, introduced new automated equipment, optimized the production process, and the result?

In just one year, productivity increased by 40% and product quality problems were reduced by 30%. Yes, this is the power of a production management strategy, and now that this power is in your hands, what are you going to do with it?

Always remember that a plan it not sacred, you need to constantly evaluate and revise it. Take a day each month to evaluate how your work plan is going, do you need to make adjustments?

What needs attention? What is going well and what needs improvement? Remember, it’s only through feedback that you can bring the program to life and help you reach your goals.

Well, let’s all get energized for the second half of 2024! With our own hands, intelligence and perseverance, we can definitely reach the peak of the production line!

If you find new problems in practice, or have a better solution, welcome to leave a message to share, we can make progress together, together to meet a better 2024!

Dedicated to the hidden champion in the field of digital intelligent equipment manufacturing in the electrical industry, creating a new and efficient automation model

Dedication Innovation Exploration

Address: No.2-1, Baixiang Avenue, Beibaixiang Town, Yueqing City, P.R. China

Tel: +86577-62777057, 62777062

Email: zzl@benlongkj.cn

Website: www.benlongkj.com

Post time: Mar-17-2024