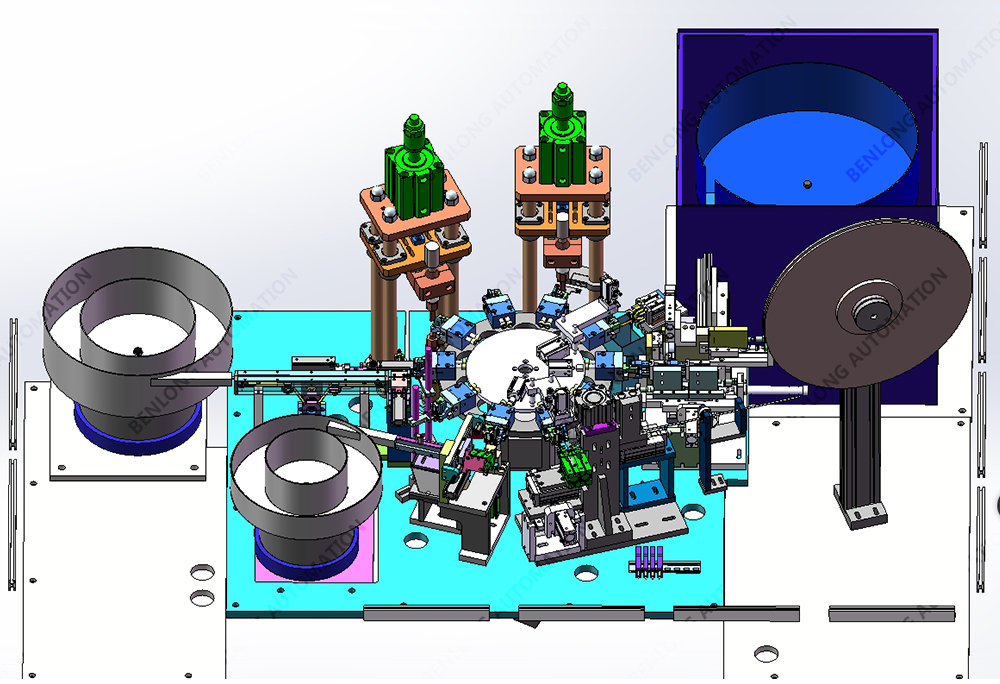

MCB electromagnetic component thermal release system large bracket automatic welding equipment

See More>>Efficiency:

Automatic welding equipment can significantly improve production efficiency by reducing manual intervention and waiting time through continuous welding operations.

The welding speed is usually fast and can complete a large number of bracket welding work in a short period of time.

Accuracy:

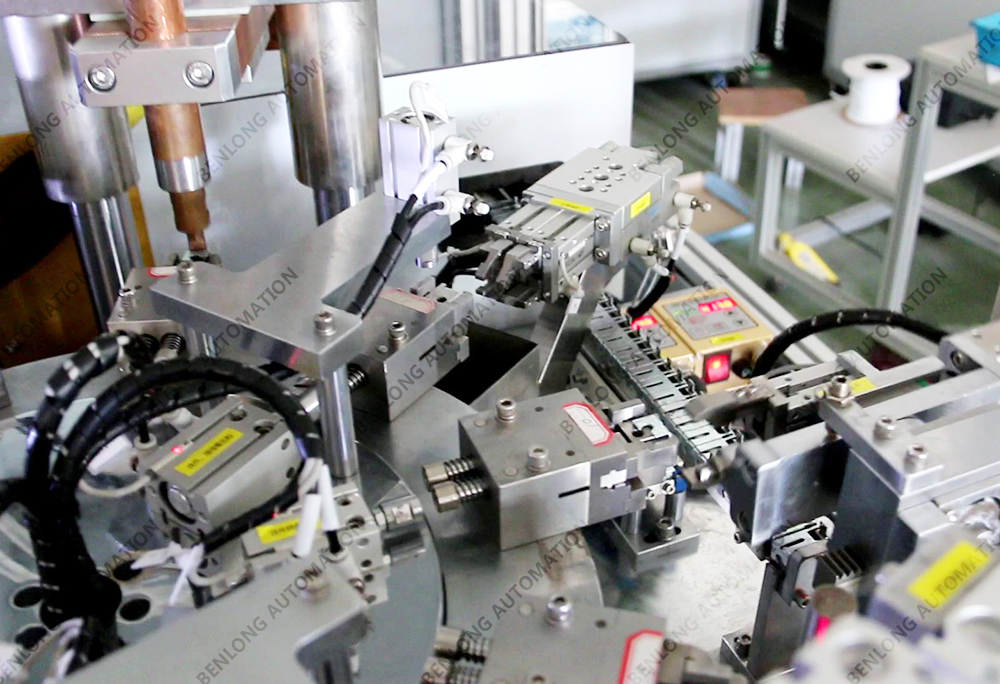

Automatic welding equipment usually uses high-precision control systems to ensure the accuracy of welding positions.

Through preset welding parameters and programs, precise control of the welding process can be achieved, ensuring consistency and stability of welding quality.

Reliability:

Automatic welding equipment usually adopts advanced welding technology and materials, with high reliability and durability.

The equipment can operate stably for a long time, reduce failures and downtime, and improve the overall reliability of the production line.

Flexibility:

Automatic welding equipment usually has multiple welding modes and parameter settings, which can adapt to the welding needs of different models and specifications of MCB thermal release system large brackets.

By adjusting welding parameters and procedures, it is possible to weld supports of different materials and thicknesses.

1. Equipment input voltage 380V ± 10%, 50Hz; ±1Hz;

2. The device can be designed to be compatible with multiple sizes.

3. Equipment production cycle time: ≤ 3 seconds per piece.

4. The equipment has the function of automatic statistical analysis of OEE data.

5. When switching production between products of different specifications, manual replacement of molds or fixtures is required.

6. Welding time: 1~99S. Parameters can be set arbitrarily.

7. The equipment has alarm display functions such as fault alarm and pressure monitoring.

8. There are two operating systems: Chinese version and English version.

9. All core components are imported from different countries and regions such as Italy, Sweden, Germany, Japan, the United States, and Taiwan.

10. The device can be equipped with functions such as “Smart Energy Analysis and Energy Management System” and “Intelligent Equipment Service Big Data Cloud Platform”.

11. Having independent and proprietary intellectual property rights