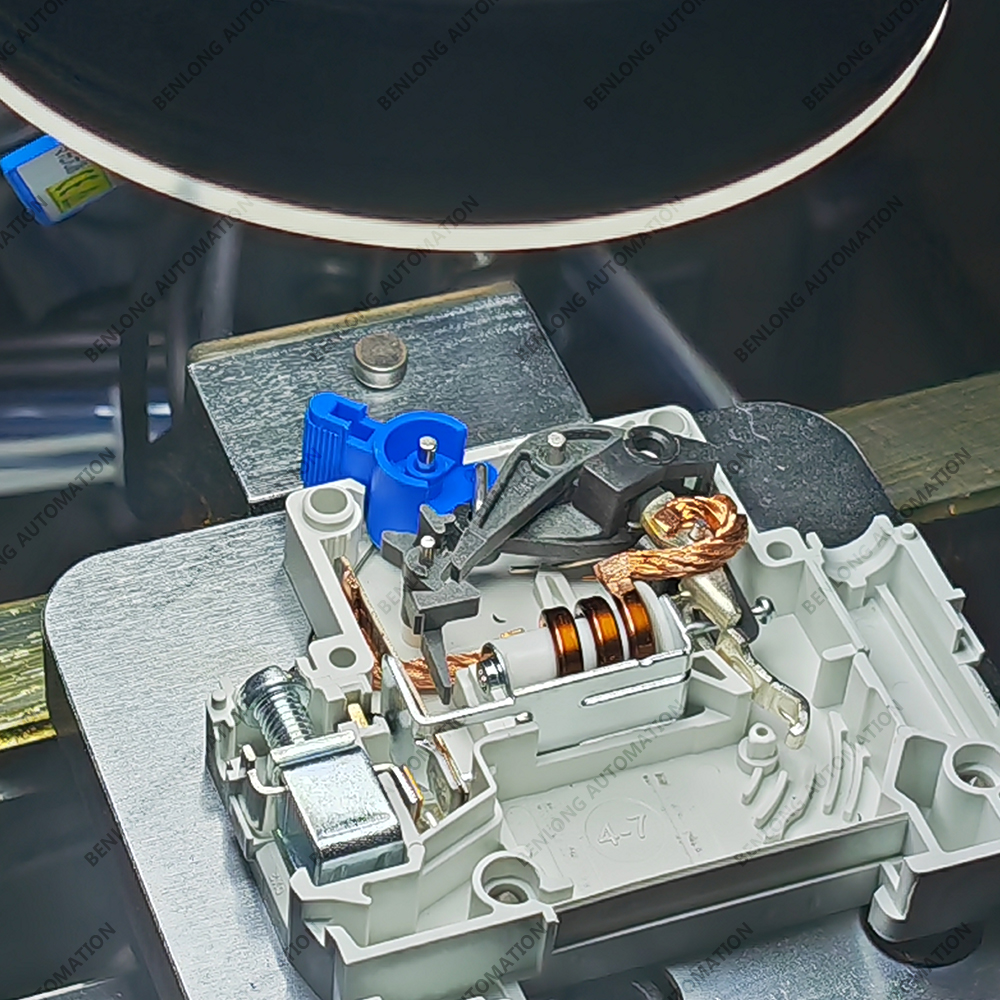

MCB automatic assembly line

See More>>1. Applicable products of assembly equipment include:

(AC type) MCB miniature circuit breaker, (DC type) MCB miniature circuit breaker

2. Equipment system features:

Adopt multi-specification mixed production, automation, informationization, modularization, flexibility, customization, visualization, cloud computing, one-key switching, early warning notification, evaluation report, data collection and processing, global detection management, equipment full life cycle management, more advanced, smarter, more reliable, highly integrated, intelligent scheduling, remote maintenance design concept.

3. Equipment functions:

It has the functions of automatic shell loading, cover opening, automatic assembly of arc-isolating sheets, magnetic sheets, 7-shaped sheets, large springs, handle springs, adjusting screws, magnetic components, terminal components, core components, double-metal components, locks, lock shafts, handle shafts, handles, jump buckles, jump buckle shafts, U-shaped parts, roller needles, terminal posts, terminal screws, arc-starting sheets, extinguishing shields, double-metal automatic pre-adjustment, CCD visual inspection, unloading, material shortage alarm, automatic distinction of defective products, etc., online monitoring, real-time monitoring, quality traceability, barcode recognition, life monitoring of key components, data storage, networking of MES system and ERP system, equipment-level information collection and data processing, arbitrary parameter formulation, smart energy analysis and energy-saving management system, smart equipment service big data cloud platform, etc.

MCB automatic assembly line