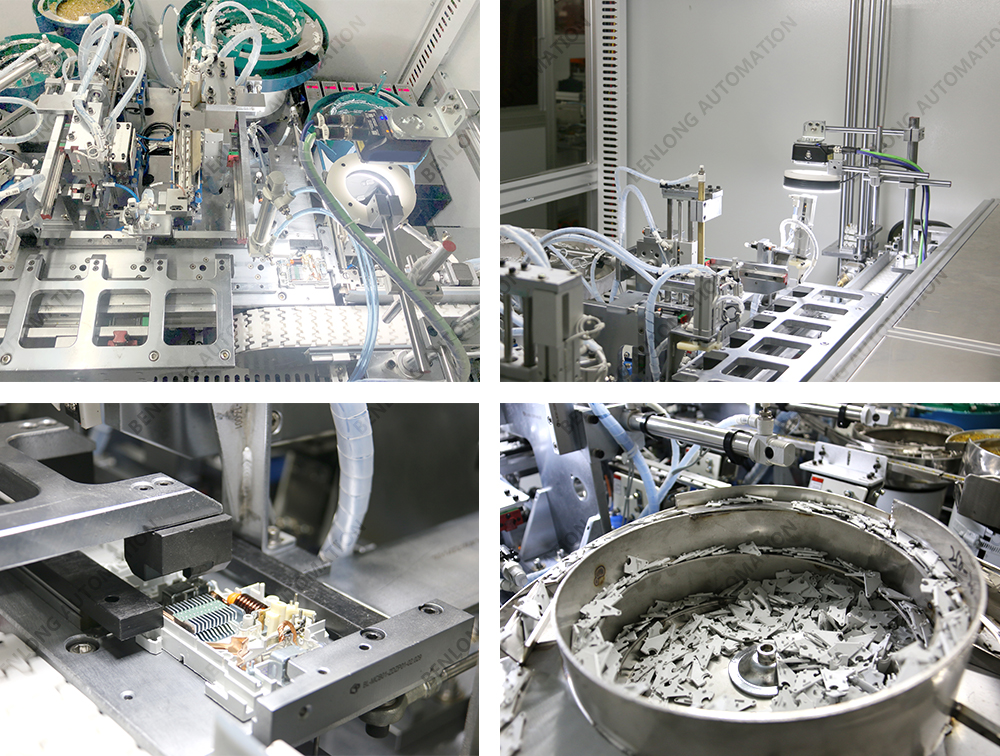

MCB automatic assembly equipment

See More>>1, equipment input voltage using three-phase five-wire system 380V ± 10%, 50Hz; ± 1Hz;

2, equipment compatible poles: 1P, 2P, 3P, 4P, 1P + module, 2P + module, 3P + module, 4P + module.

3, equipment production beat or production efficiency: 1 second/pole, 1.2 seconds/pole, 1.5 seconds/pole, 2 seconds/pole, 3 seconds/pole; five different specifications of the equipment, the enterprise can choose different configurations according to different production capacity and investment budget.

4, the same shell frame products, different poles can be switched by one key or sweep code switching; switching products need to manually replace the mold or fixture.

5、Assembly mode: manual assembly, semi-automatic man-machine combination assembly, automatic assembly can be optional.

6, defective product detection: CCD vision detection or fiber optic sensor detection of two configurations.

7、Assembly parts feeding mode is vibrating disk feeding; noise ≤ 80 dB.

8, equipment fixture can be customized according to the product model.

9, the equipment has a fault alarm, pressure monitoring and other alarm display function.

10, the equipment operating system adopts the Chinese version and English version of the two operating systems, a key to switch, convenient and quick.

11, all core parts are used in Italy, Sweden, Germany, Japan, the United States, Taiwan and other countries and regions in the world’s top ten brands of well-known companies.

12, the equipment design of “intelligent energy analysis and energy saving management system” and “intelligent equipment service big data cloud platform” function can be optional according to customer demand.

13、The equipment has obtained national patents and related intellectual property rights.