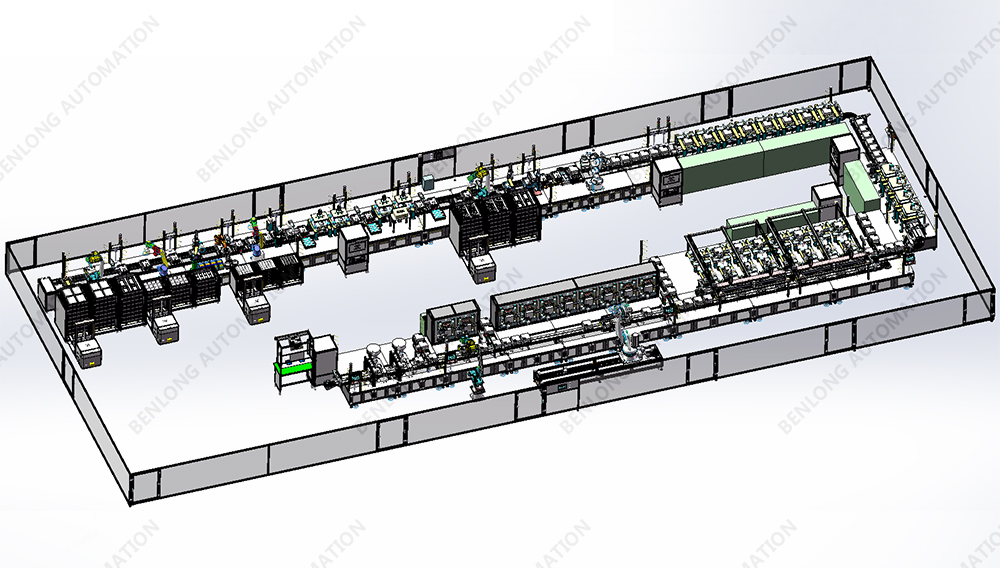

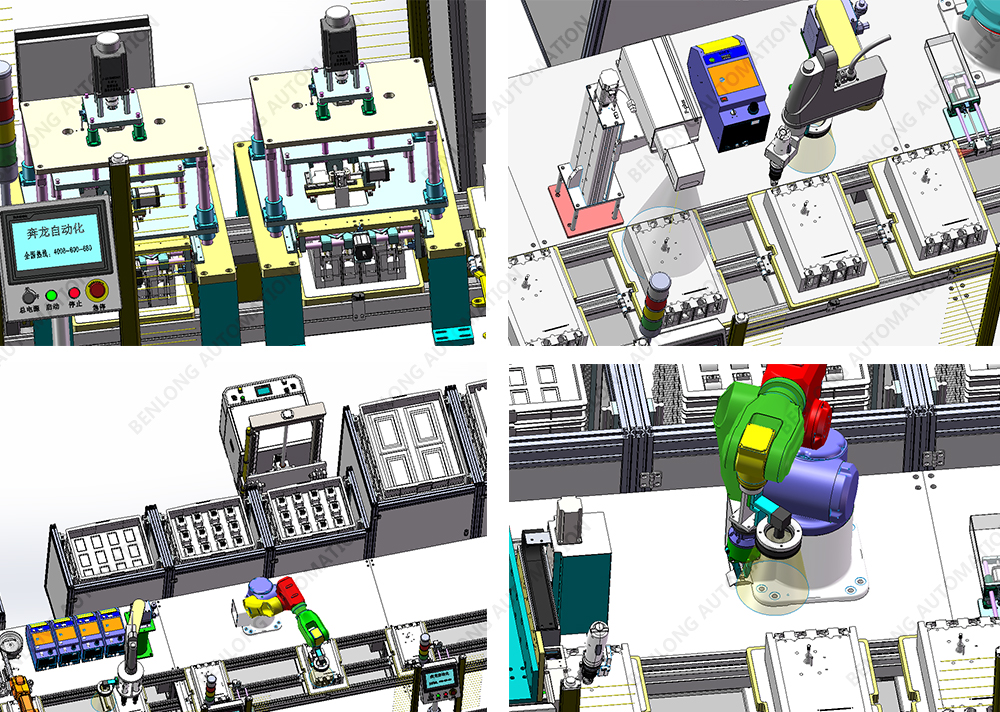

Equipped with product base AGV automatic feeding, robot automatic grasping, CCD visual automatic detection, magnetic control mechanism automatic feeding, robot automatic assembly, CCD visual automatic detection, automatic screw locking, automatic feeding of opening and closing indicator, robot automatic assembly, CCD visual automatic detection, automatic screw locking, automatic mechanical running-in, automatic circuit resistance detection, automatic voltage resistance detection, automatic feeding of upper cover part, robot automatic assembly CCD visual automatic detection, automatic screw locking, automatic assembly of upper cover and base, automatic screw locking, automatic laser marking QR code, CCD visual automatic detection, software engineering automatic configuration, automatic detection, product information writing/communication/hardware function detection, automatic terminal connection, automatic key switching, CCD visual automatic detection, automatic detection of four quadrant electricity metering, current calibration, voltage calibration, active power, reactive power Apparent power, power factor, phase, frequency, harmonics, Bluetooth, overvoltage, undervoltage, voltage loss, timing, RS485 communication, leakage current detection, leakage current detection, short circuit short delay detection, short circuit instantaneous detection, backup protection detection, automatic locking of terminal block screws, automatic laser marking, CCD visual automatic detection, automatic reading of QR codes, identification of qualified and unqualified products, automatic packaging, automatic stacking, AGV logistics Assembly, online detection, real-time monitoring, quality traceability, barcode recognition, component life monitoring, data storage, MES system and ERP system networking, parameter arbitrary formula, intelligent energy analysis and energy-saving management system, intelligent equipment service big data cloud platform, and other functions for processes such as material shortage alarm.