Internet of Things intelligent miniature circuit breaker automatic electronic integrated testing equipment

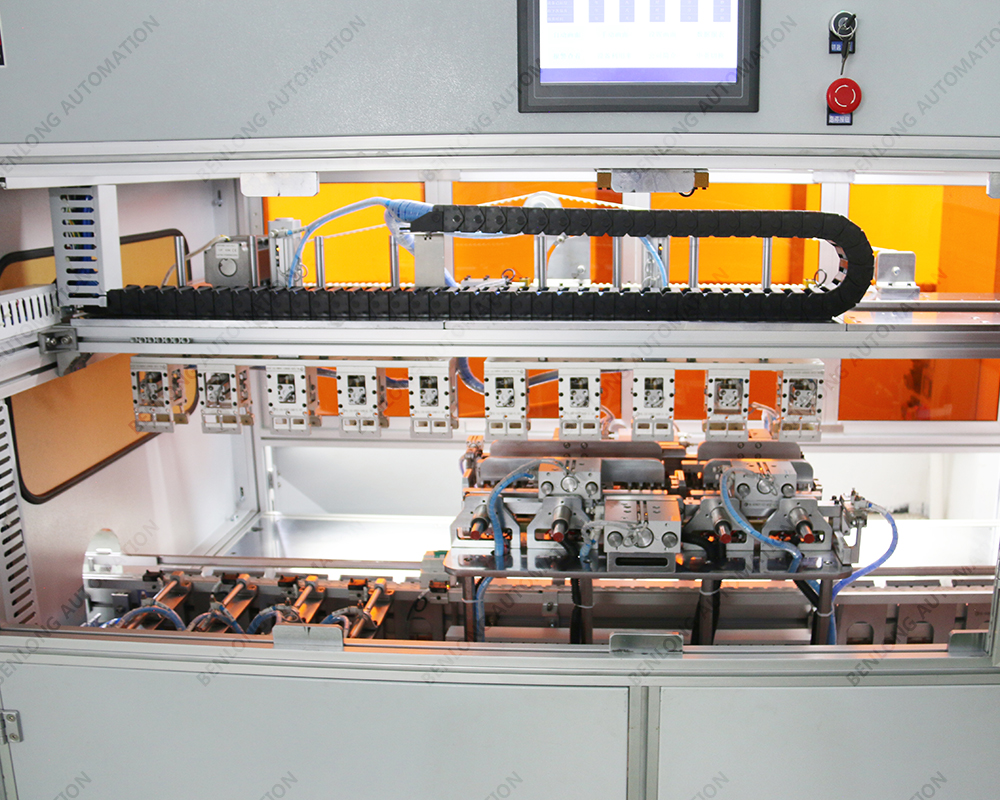

See More>>1. Equipment input voltage: 380V ± 10%, 50Hz; ± 1Hz;

2. Device compatible poles: 1P+module, 2P+module, 3P+module, 4P+module.

3. Equipment production rhythm: 30 seconds to 90 seconds per unit, specific based on customer product testing projects.

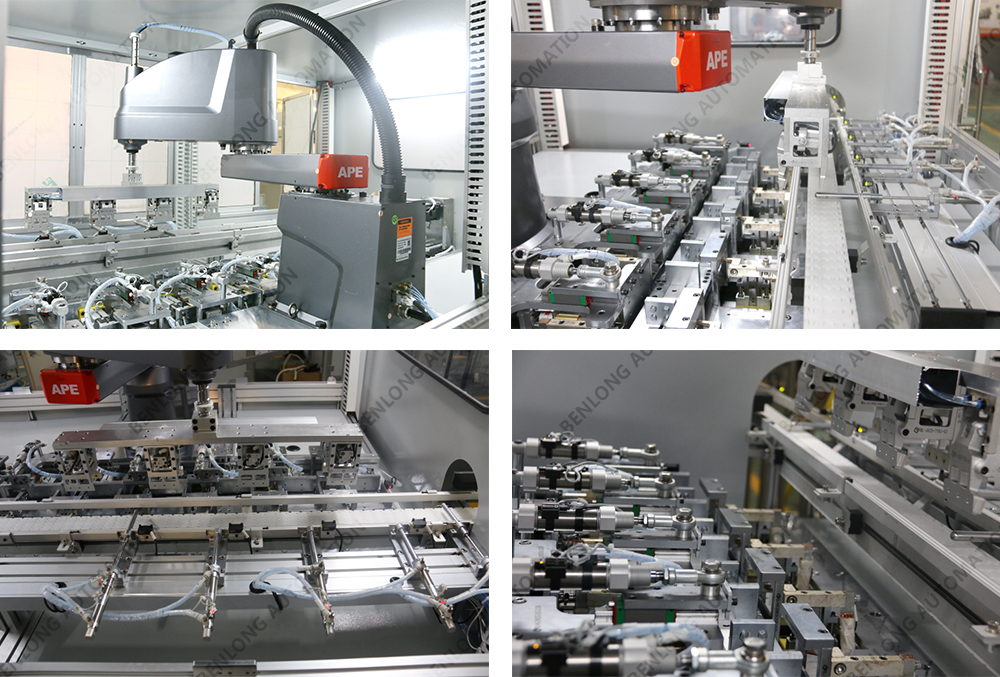

4. The same shelf product can be switched between different poles with one click or scan code switching; Different shell frame products require manual replacement of molds or fixtures.

5. Compatible product types: A type, B type, C type, D type, 132 specifications for A type leakage characteristics of AC circuit breakers, 132 specifications for AC type leakage characteristics of AC circuit breakers, 132 specifications for AC circuit breakers without leakage characteristics, 132 specifications for DC circuit breakers without leakage characteristics, and a total of ≥ 528 specifications available.

6. The number of times the device detects products: 1-99999, which can be set arbitrarily.

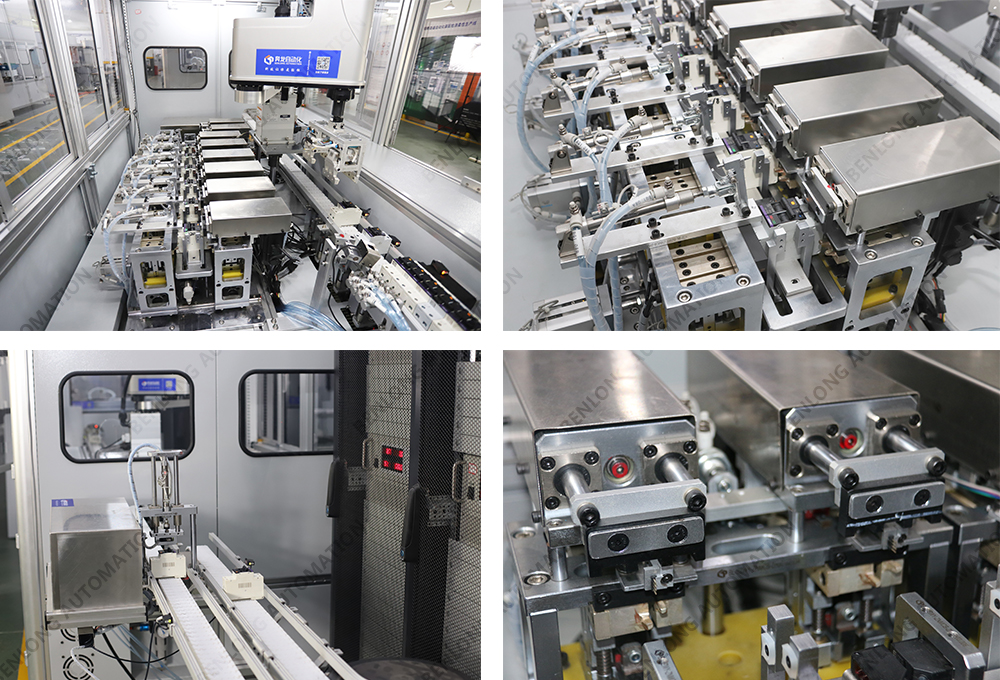

7. The loading and unloading methods of this device include two options: robot or pneumatic finger.

8. Equipment and instrument accuracy: in accordance with relevant national execution standards.

9. The equipment has alarm display functions such as fault alarm and pressure monitoring.

10. There are two operating systems available: Chinese and English.

11. All core accessories are imported from different countries and regions such as Italy, Sweden, Germany, Japan, the United States, Taiwan, etc.

12. The device can be equipped with functions such as the “Smart Energy Analysis and Energy Conservation Management System” and the “Smart Equipment Service Big Data Cloud Platform”.

13. Having independent and independent intellectual property rights.