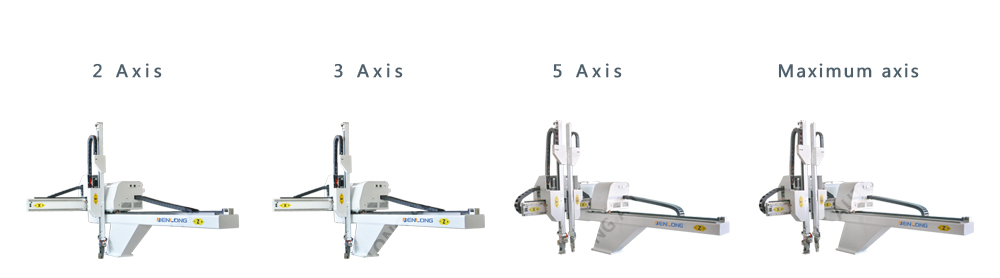

Injection molding manipulator

See More>>

Power supply: 1CAC220V+10V50/60HZ

Working air pressure: 5kgf/cm20.49Mpa

Maximum allowable air pressure: 8kgf/cm0.8Mpa

Drive method: XZ inverter ypeneumatic Cylinder

Zezi:90FixedPneumatic

control system

NC Control

Write your message here and send it to us