Energy meter external low voltage circuit breaker automatic piercing and riveting equipment

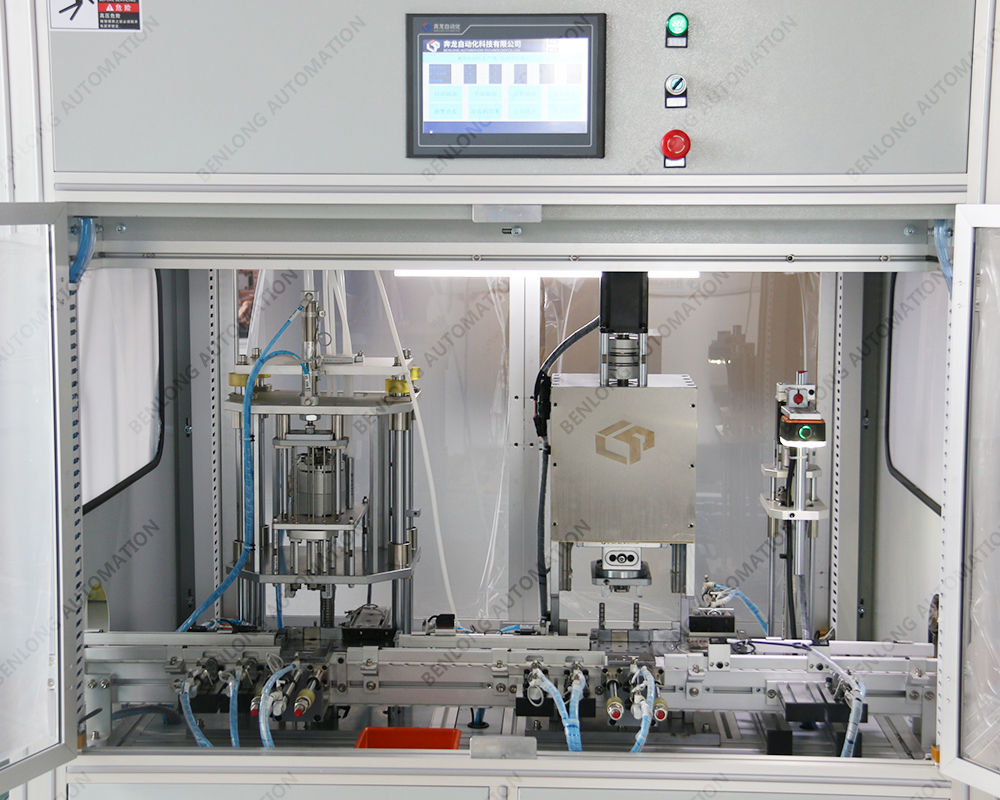

See More>>1. Equipment input voltage: 220V/380V ± 10%, 50Hz; ± 1Hz;

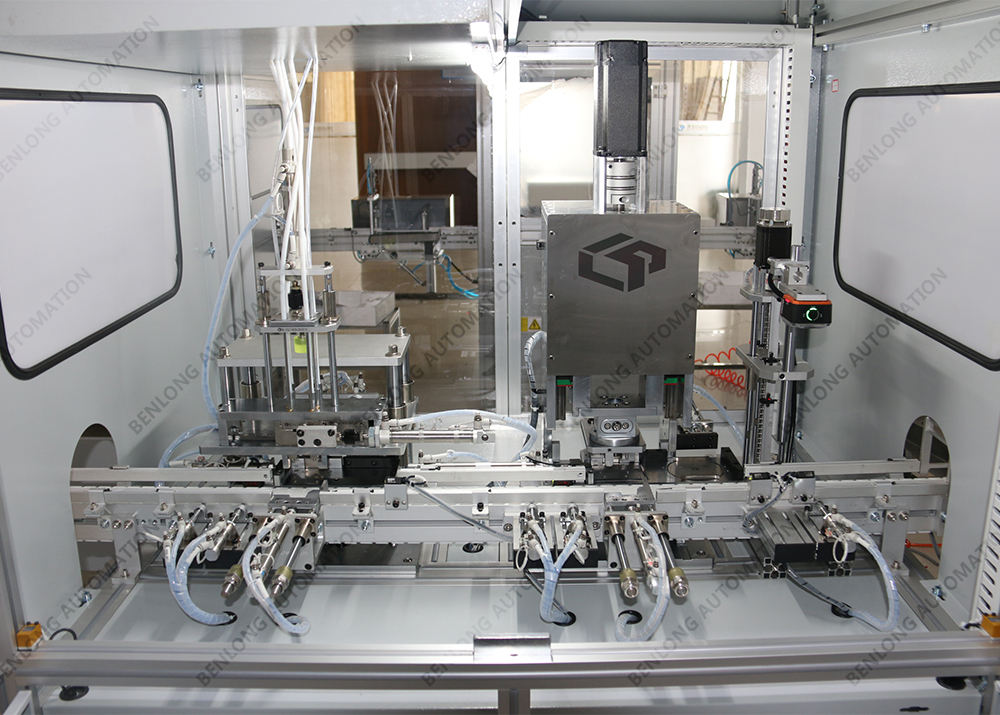

2. Device compatibility poles: 1P, 2P, 3P, 4P, 1P+module, 2P+module, 3P+module, 4P+module.

3. Equipment production rhythm: ≤ 10 seconds per pole.

4. The same shelf product can be switched between different poles with just one click or by scanning the code; Different shell products require manual replacement of molds or fixtures.

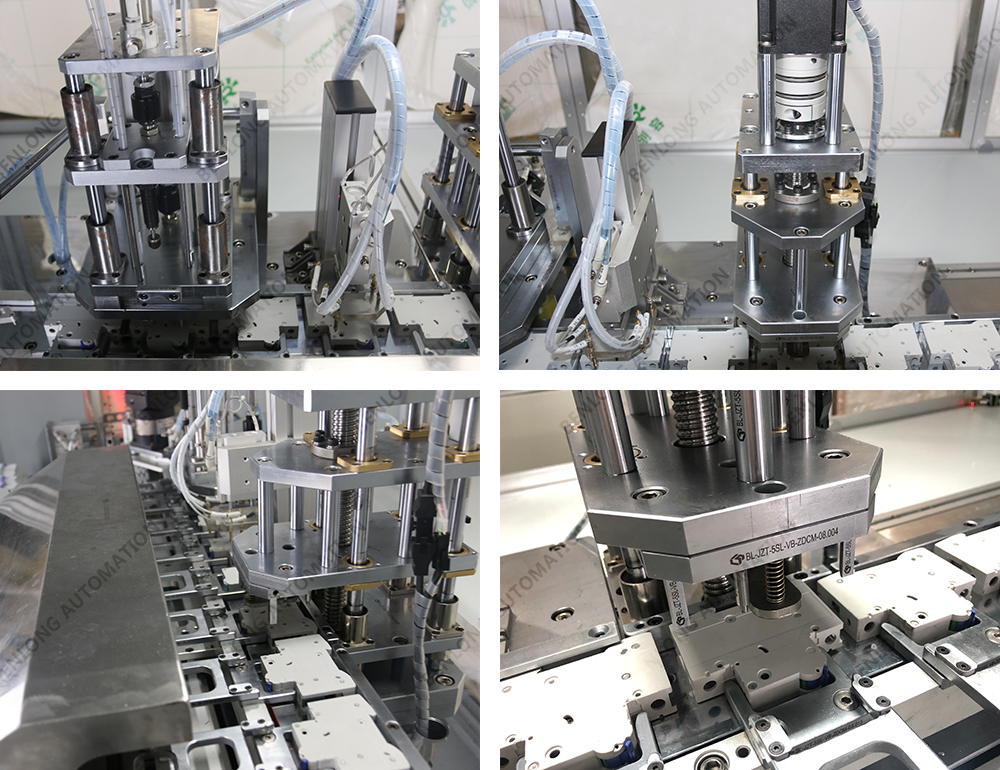

5. The rivet feeding method is vibration disc feeding; Noise ≤ 80 decibels; The number of rivets and molds can be customized according to the product model.

6. The speed and vacuum degree parameters of the nail splitting mechanism can be set arbitrarily.

7. There are two optional riveting forms: cam riveting and servo riveting.

8. The riveting speed parameters can be set arbitrarily.

9. The equipment has alarm display functions such as fault alarm and pressure monitoring.

10. There are two operating systems available: Chinese and English.

11. All core accessories are imported from different countries and regions such as Italy, Sweden, Germany, Japan, the United States, and Taiwan.

12. The equipment can be optionally equipped with functions such as the Smart Energy Analysis and Energy Conservation Management System and the Smart Equipment Service Big Data Cloud Platform.

13. Having independent independent intellectual property rights. (