Dual electric automatic transfer switch automatic voltage withstand testing equipment

See More>>1. Equipment input voltage 380V ± 10%, 50Hz; ± 1Hz;

2. Device compatible poles: 1P, 2P, 3P, 4P, 1P+module, 2P+module, 3P+module, 4P+module

3. Equipment production rhythm: 1 second per pole, 1.2 seconds per pole, 1.5 seconds per pole, 2 seconds per pole, and 3 seconds per pole; Five different specifications of equipment.

4. The same shelf product can be switched between different poles with one click or scan code switching; Different shell frame products require manual replacement of molds or fixtures.

5. High voltage output range: 0-5000V; The leakage current is 10mA, 20mA, 100mA, and 200mA, which can be selected in different levels.

6. Detection of high-voltage insulation time: The parameters can be set arbitrarily from 1 to 999S.

7. Detection frequency: 1-99 times. The parameter can be set arbitrarily.

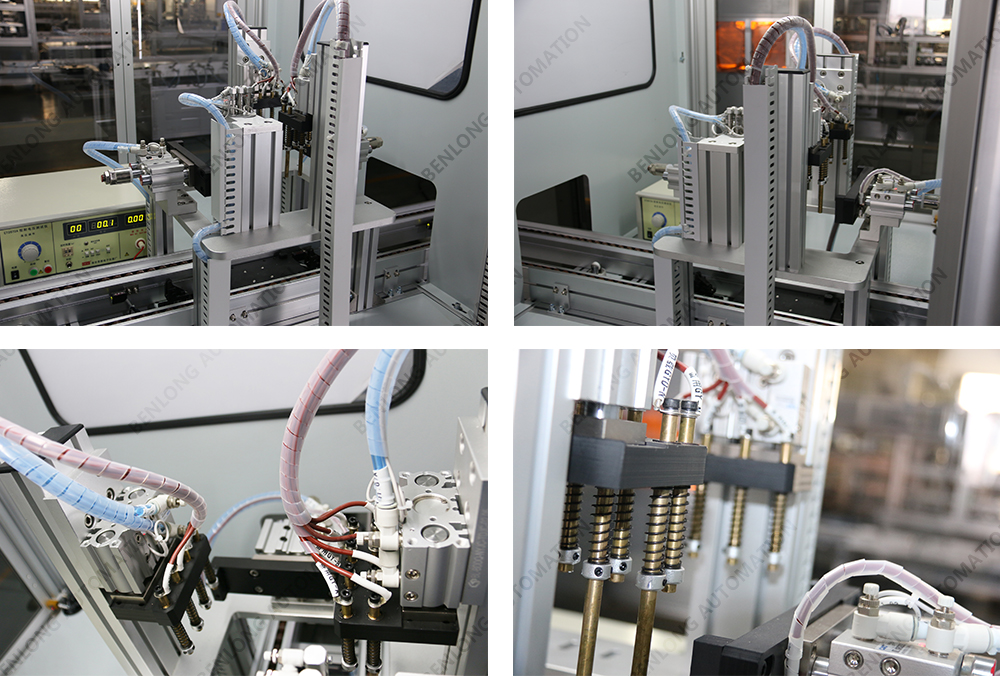

8. High voltage detection part: When the product is in a closed state, detect the voltage resistance between phases; When the product is in a closed state, detect the voltage resistance between the phase and the bottom plate; When the product is in a closed state, detect the voltage resistance between the phase and the handle; When the product is in an open state, detect the voltage resistance between the incoming and outgoing lines.

9. Optional for testing when the product is in a horizontal state or when the product is in a vertical state.

10. The equipment has alarm display functions such as fault alarm and pressure monitoring.

11. There are two operating systems available: Chinese and English.

12. All core accessories are imported from different countries and regions such as Italy, Sweden, Germany, Japan, the United States, Taiwan, etc.

13. The device can be equipped with functions such as the “Smart Energy Analysis and Energy Conservation Management System” and the “Smart Equipment Service Big Data Cloud Platform”.

14. Having independent and independent intellectual property rights