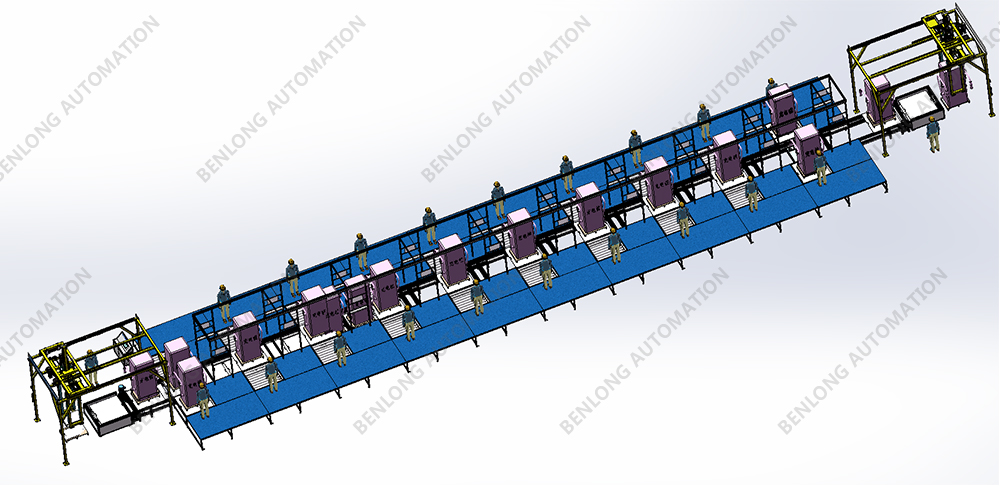

DC charging pile automatic production line

See More>>Applicable assembly: DC charging pile, AC charging pile, single head charging pile, multi head charging pile, floor standing charging pile, wall mounted charging pile

Equipment functions: Automated conveying system, workstation assistance – lighting fan, air path, slide hook socket, air source interface, process display screen, material calling system, scanning and storage system, etc

Regional division: assembly area, testing area, aging area, testing area, sealing test, special protection test, packaging and palletizing area

Production site requirements: production area, material storage area, logistics channel, finished product storage area, office area, and special facility installation and placement area

Basic requirements for charging station assembly line:

A. Production capacity and cycle time of charging pile assembly line: 50 units/8h; Basic production cycle: 1 unit/min, production time: 8h/shift, 330 days/year.

B. Total length of charging pile assembly line: assembly line 33.55m; Assembly line to be inspected 5m, testing line 18.5m

C. Maximum weight of charging pile assembly line pile body: 200kg

D. Maximum external dimensions of pile body: 1000X1000X2000 (mm)

E. Charging pile assembly line height: 400mm.

F. Total gas consumption: The compressed air pressure is 7kgf/cm2, and the flow rate does not exceed 0.5m3/min (excluding the gas consumption of pneumatic tools and pneumatic assisted robotic arms).

G. Total electricity consumption: The entire assembly line shall not exceed 30KVA.

H. Charging pile assembly line noise: The overall noise of the line is less than 75dB (tested at a distance of 1m from the noise source).

I. The charging pile assembly line conveyor body and various specialized machines are designed with advanced and reasonable technology, with a high degree of automation. The logistics meet the requirements of the process route, and the production line will not experience congestion or blockage; The line structure is firm and stable, with a unified appearance style.

J. The charging pile assembly line has sufficient stability and strength under normal working conditions.

K. The overhead line body of the charging pile assembly line must have sufficient strength, rigidity, and stability, and will not pose a threat to personnel safety; There are corresponding protective devices and safety warning signs in places where special planes and equipment may endanger personal safety.

Basic requirements for charging station assembly line:

A. Production capacity and cycle time of charging pile assembly line: 50 units/8h; Basic production cycle: 1 unit/min, production time: 8h/shift, 330 days/year.

B. Total length of charging pile assembly line: assembly line 33.55m; Assembly line to be inspected 5m, testing line 18.5m

C. Maximum weight of charging pile assembly line pile body: 200kg

D. Maximum external dimensions of pile body: 1000X1000X2000 (mm)

E. Charging pile assembly line height: 400mm.

F. Total gas consumption: The compressed air pressure is 7kgf/cm2, and the flow rate does not exceed 0.5m3/min (excluding the gas consumption of pneumatic tools and pneumatic assisted robotic arms).

G. Total electricity consumption: The entire assembly line shall not exceed 30KVA.

H. Charging pile assembly line noise: The overall noise of the line is less than 75dB (tested at a distance of 1m from the noise source).

I. The charging pile assembly line conveyor body and various specialized machines are designed with advanced and reasonable technology, with a high degree of automation. The logistics meet the requirements of the process route, and the production line will not experience congestion or blockage; The line structure is firm and stable, with a unified appearance style.

J. The charging pile assembly line has sufficient stability and strength under normal working conditions.

K. The overhead line body of the charging pile assembly line must have sufficient strength, rigidity, and stability, and will not pose a threat to personnel safety; There are corresponding protective devices and safety warning signs in places where special planes and equipment may endanger personal safety.

DC charging pile automatic production line