Material Conveying: Chain conveyor lines are capable of horizontal, inclined and vertical conveying of materials, providing efficient and stable material transport solutions for the production process. This kind of conveying line can handle various materials, including food, beverage, chemical raw materials, auto parts, etc., and has wide applicability.

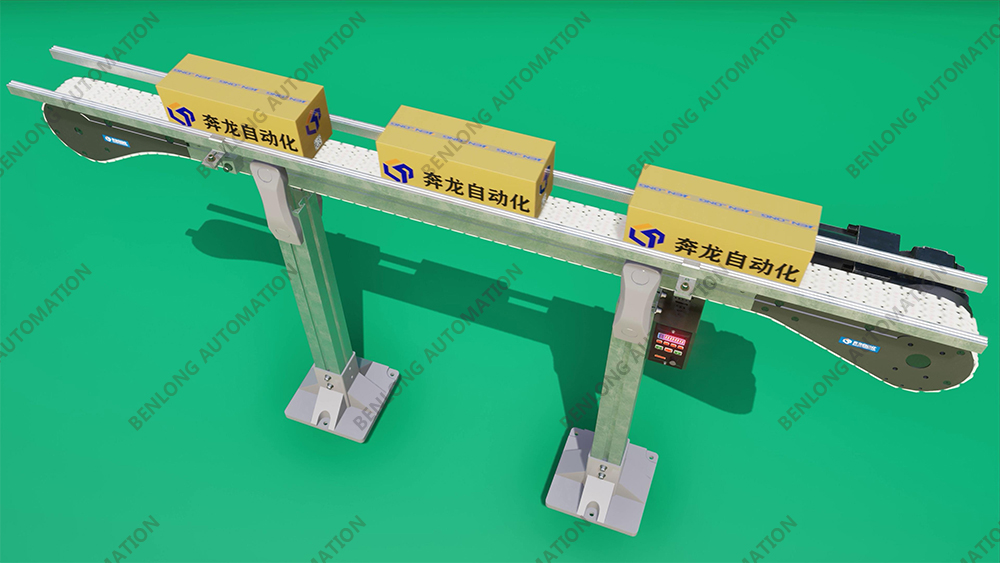

Structural features: chain plate conveying line is composed of chain, chain groove, chain plate and other components, compact structure, small footprint, suitable for production sites with limited space. The surface of chain plate is flat, suitable for conveying surface sensitive materials, such as glass bottles, fragile products, etc., which can ensure the integrity of the products.

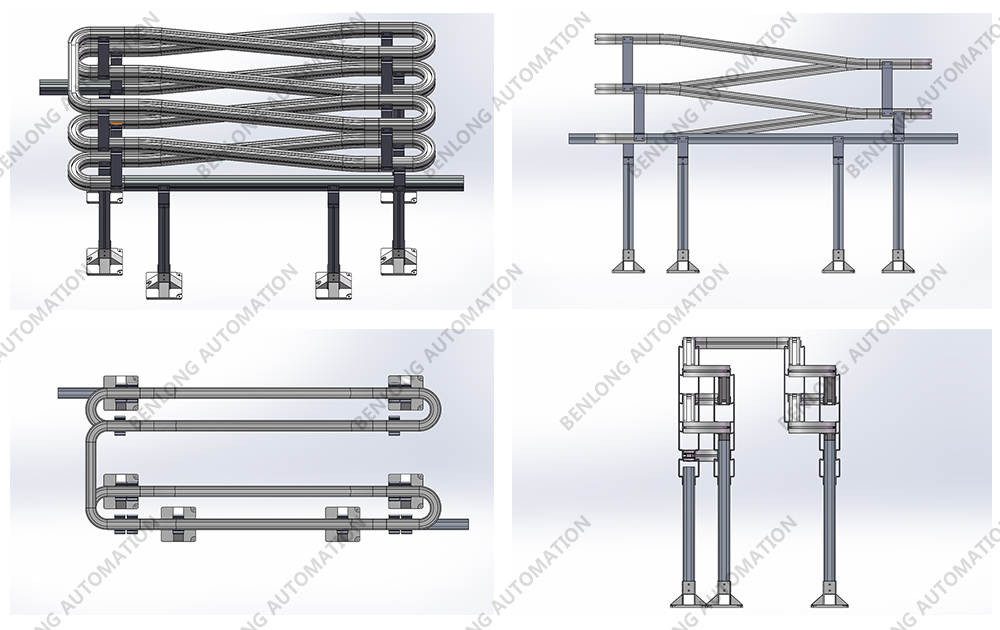

Performance Advantage: Chain plate conveying line has the advantages of large transmission torque, strong bearing capacity, fast conveying speed and high stability. At the same time, due to its structural characteristics, the chain plate conveying line can adapt to long-distance conveying and the bendability of the transport line, which makes the material conveying more flexible and efficient.

Application Scenario: Chain conveyor line is widely used in many industries, including food processing, automobile manufacturing, chemical production, pharmaceutical and chemical industry, packaging and logistics, electronic products and automobiles. Its smooth conveying surface and easy cleaning make it ideal for the food processing industry; while in the pharmaceutical and chemical industries, chain conveyor lines are able to meet the special needs of occasions with high hygiene and cleanliness.

Intelligence and automation: With the development of intelligent manufacturing, chain conveyor lines are also improving towards intelligence and automation. By adding sensors, PLC control system and other equipment, the automatic detection, fault diagnosis and remote control of the conveyor line are realised, which improves the production efficiency and manufacturing quality.

Customisability: The chain plate material of the chain conveyor line can be selected according to the actual needs, such as carbon steel, stainless steel, thermoplastic chain and so on. Meanwhile, the layout of the equipment is flexible, which can complete horizontal, inclined and turning conveying on one conveying line to meet the needs of different production lines.