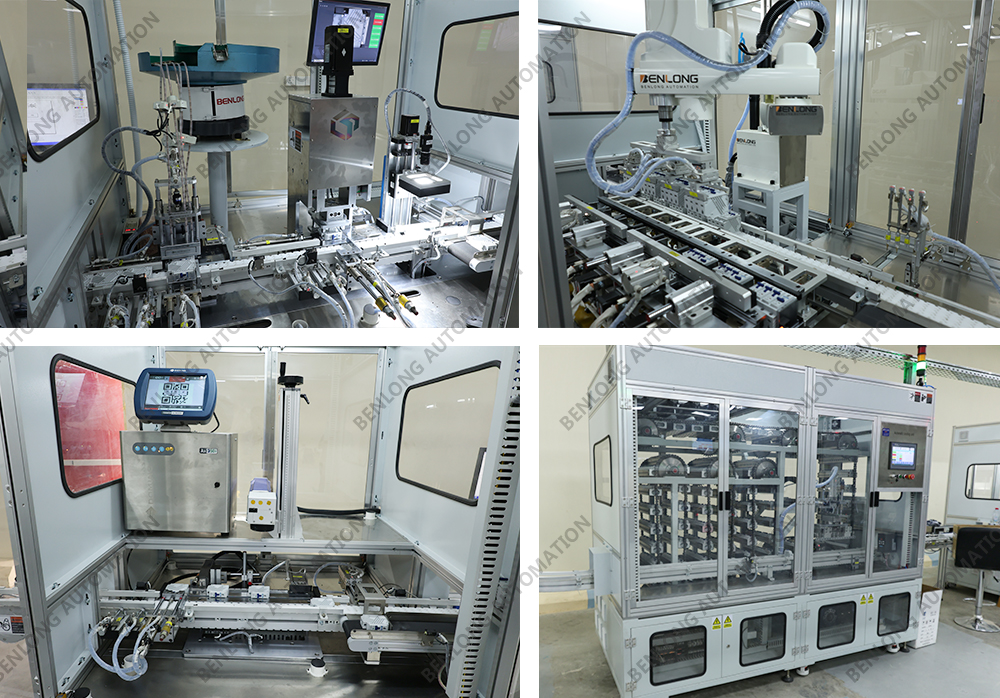

MCB automated equipment test production line

See More>>The processes of the production line include: automatic assembly, automatic assembly, automatic coding, automatic nail threading, automatic riveting, automatic instantaneous, automatic time-delay, automatic cooling, automatic time-delay recalibration, automatic mechanical characteristics, automatic pass/fail, automatic pressure resistance, automatic pad-printing, automatic laser marking, automatic mounting of snap/stop parts, manual packing table, robotic palletising and loading and unloading, MES system data storage, SOP electronic display screen, etc., compatible with the production of 1P, 2P, 3P, 4P, B-type, C-type, D-type, 18-module or 27-module, etc., the production line has online testing, real-time monitoring, quality traceability, bar code or two-dimensional code automatic identification and reading, life monitoring of components, the system and the ERP system networking, the parameter of the arbitrary formula, intelligent energy analysis and energy-saving management system, intelligent equipment services, big data platform and other functions, each machine is made by Benny. Functions, each machine is designed and developed by Penlong Automation independently, software programming, you can control the machine operation through the display screen, it has a lack of material alarm, report faults, tracking product production data, OEE data, etc., which is conducive to lean production, troubleshooting, timely replenishment, etc., the operating system supports multi-language design. The core parts of the equipment are all from the world famous brand suppliers such as Germany, Italy, Japan, UK, USA, etc. It can help your factory save more manpower and time, realise factory automation and grab more market share for you.

1、Equipment input voltage:380V±10%,50Hz;±1Hz;

2、equipment compatible: 1P, 2P, 3P, 4P, B type, C type, D type, 18 modulus or 27 modulus.

3、equipment production beat: 1 second / pole, 1.5 seconds / pole, 2 seconds / pole, 2.4 seconds / pole, 3 seconds / pole, 5 seconds / pole six optional.

4、the same shell frame products, different poles can be switched by one key or scanning code; switching different shell frame products need to manually replace the mould or fixture.

5、Assembly mode: manual assembly, automatic assembly can be optional.

6、Equipment fixture can be customised according to the product model.

7、Equipment with fault alarm, pressure monitoring and other alarm display function.

8、Chinese and English version of the two operating systems.

9、All core parts are imported from different countries and regions such as Italy, Sweden, Germany, Japan, the United States, Taiwan and so on.

10, the equipment can be optional “intelligent energy analysis and energy saving management system” and “intelligent equipment service big data cloud platform” and other functions.

11、Independent independent intellectual property rights