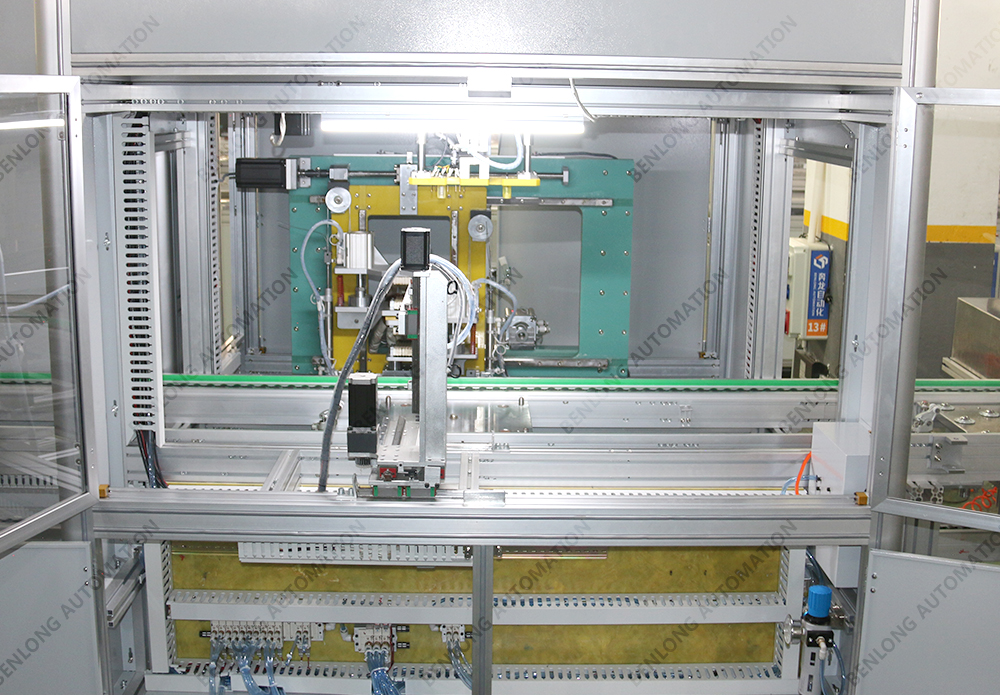

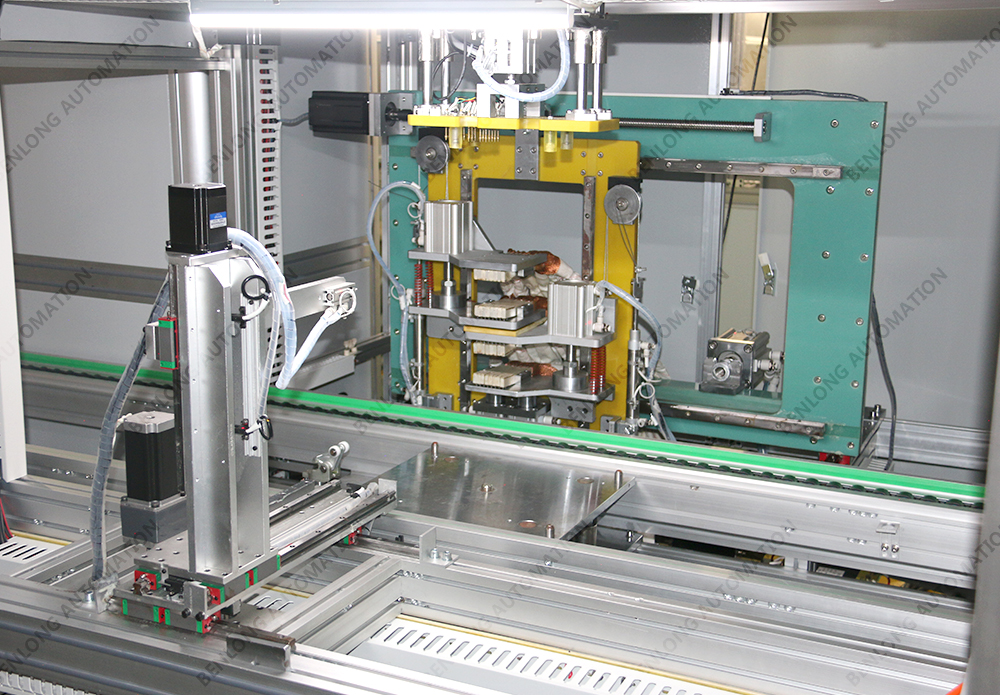

ACB automatic current characteristic testing equipment

See More>>1, equipment input voltage 380V ± 10%, 50Hz; ± 1Hz;

2、Equipment compatibility: drawer type, fixed series of products of 3-pole, 4-pole or customized according to customer requirements.

3, equipment production beat: 7.5 minutes / unit, 10 minutes / unit of two optional.

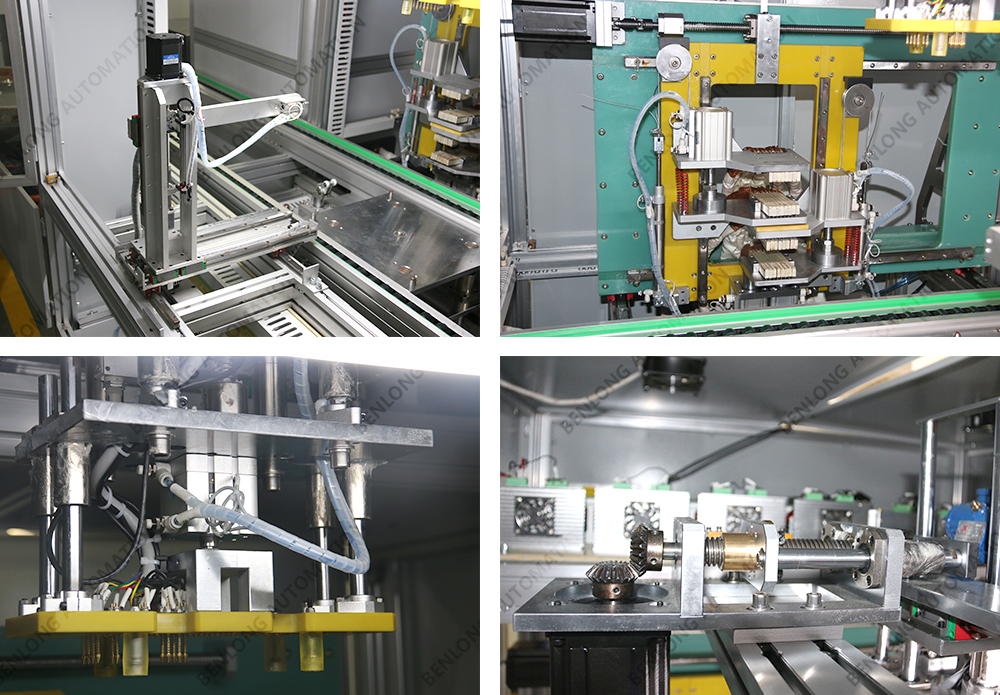

4, the same shell frame products, different poles can be switched by one key or sweep code switching; switching different shell frame products need to manually replace the mold or fixture.

5、Assembly mode: manual assembly, automatic assembly can be optional.

6、Equipment fixture can be customized according to the product model.

7、Equipment with fault alarm, pressure monitoring and other alarm display function.

8, Chinese and English version of the two operating systems.

All core parts are imported from Italy, Sweden, Germany, Japan, the United States, Taiwan and other countries and regions.

10、Equipment can be equipped with optional functions such as “Intelligent Energy Analysis and Energy Saving Management System” and “Intelligent Equipment Service Big Data Cloud Platform”.

11、It has independent independent intellectual property rights.