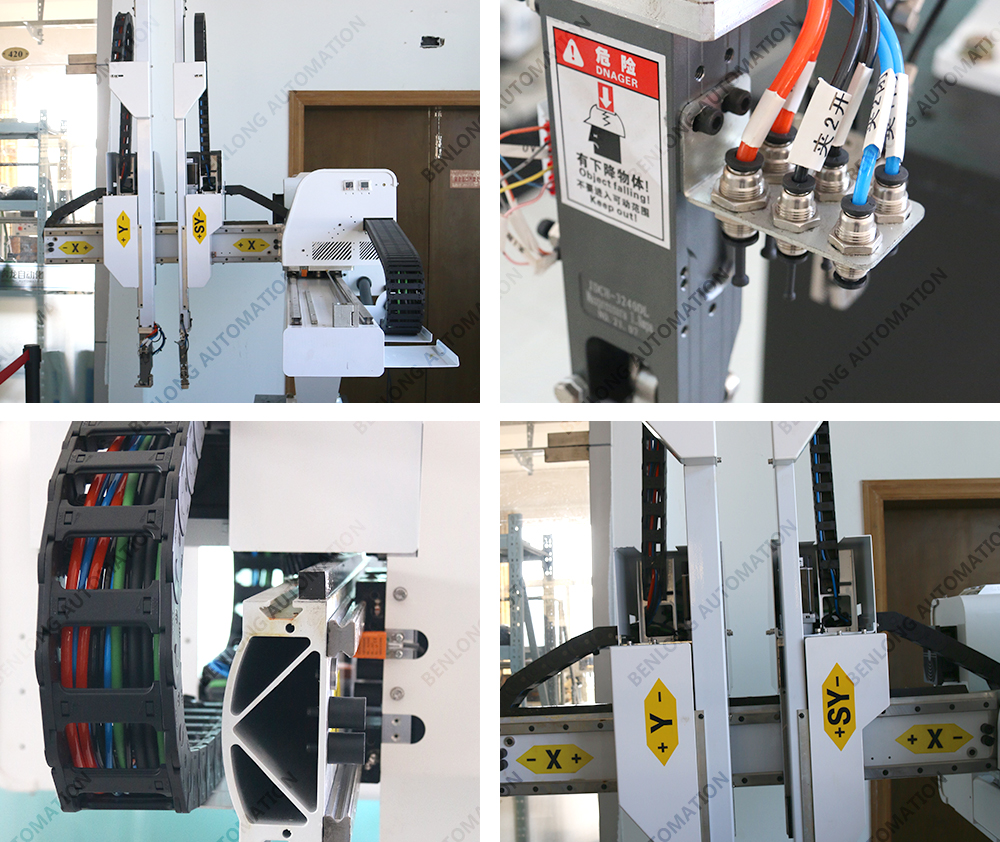

Motion control: Servo robotic arms can accurately control the motion of various joints through the control system, including rotation, translation, grasping, placement, and other actions, achieving flexible and efficient operations.

Grasping and Handling: The servo robotic arm is equipped with grabbing devices or tools, which can grab, transport, and place various objects as needed, achieving functions such as loading, unloading, handling, and stacking of objects.

Precise positioning: Servo robotic arms have precise positioning capabilities, which can be controlled by programming or sensors to accurately place objects in designated positions.

Programming control: Servo robotic arms can be controlled through programming, preset action sequences, and achieve automated operations for different tasks. Usually using instructional programming or graphical programming methods.

Visual recognition: Some servo robots are also equipped with visual recognition systems, which can recognize the position, shape, or color characteristics of the target object through image processing and analysis, and take corresponding actions based on the recognition results.

Safety protection: Servo robots are usually equipped with safety sensors and protective devices, such as light curtains, emergency stop buttons, collision detection, etc., to ensure safety during operation and prevent accidents from occurring.

Remote monitoring: Some servo robotic arms also have remote monitoring function, which can be connected through a network to achieve remote monitoring, management, and control of the robotic arm.