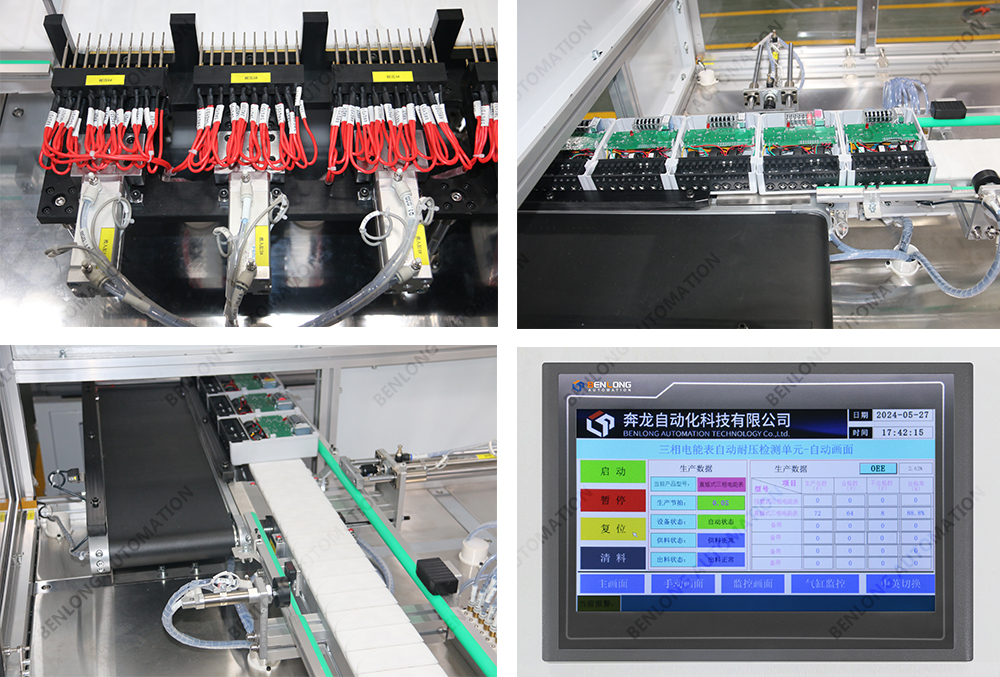

Automatic withstand voltage test equipment for power meter

See More>>With automatic product loading base, assembly of conductive columns, assembly of circuit boards, soldering, locking screws, assembly of seals, assembly of glass cover, assembly of the outer ring, locking screws, characterization testing, day-timing testing, error calibration, voltage testing, full-screen testing, comprehensive testing of the characteristics of the laser engraving, auto-labeling, carrier testing, infrared function testing, Bluetooth communication testing, recalibration testing, assembly of nameplates, scanning code asset information. Data comparison, qualified and unqualified distinction, packaging, palletizing, AGV logistics, lack of material alarms and other processes of assembly, online testing, real-time monitoring, quality traceability, barcode identification, component life monitoring, data storage, MES system and ERP system networking, parameters of any recipe, intelligent energy analysis and energy-saving management system, intelligent equipment services, big data cloud platform and other functions.

Input voltage: 220V/380V ± 10%, 50Hz; ±1Hz;

Equipment size: 1500mm · 1200mm · 1800mm (LWH)

Equipment gross weight: 200KG

Multi level compatibility: 1P, 2P, 3P, 4P

Production requirements: Daily output: 10000~30000 poles/8 hours.

Compatible products: can be customized according to product and requirements.

Operation mode: There are two options: semi-automatic and fully automatic.

Language selection: Supports customization (default in Chinese and English)

System selection: “Smart Energy Analysis and Energy Conservation Management System” and “Intelligent Equipment Service Big Data Cloud Platform”, etc.

Invention Patent: