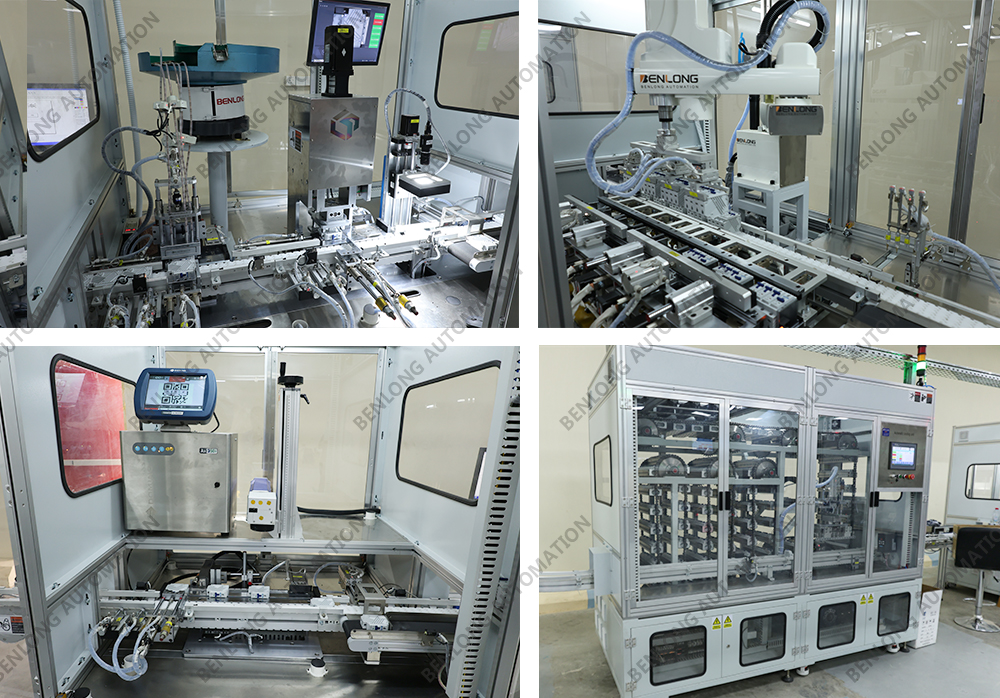

ʻO ka laina hana hoʻāʻo ʻenehana MCB

E nana hou >>ʻO nā kaʻina hana o ka laina hana: ka hui ʻakomi, ka hui ʻakomi, ka hoʻopili ʻana i ka nail, ka riveting aunoa, ka manawa koke, ka hoʻopaneʻe manawa, ka hoʻoluʻu ʻakomi, ka hoʻopaneʻe ʻana i ka manawa, nā ʻano mechanical, pass/fail, ʻO ke kūpaʻa puʻupuʻu maʻalahi, paʻi paʻi maʻalahi, ka hōʻailona laser maʻalahi, ke kau ʻana i nā ʻāpana paʻi / hoʻomaha, papa packing manual, palletising robotic a me ka hoʻouka ʻana a me ka wehe ʻana, MES system data storage, SOP electronic pale hōʻike, etc., kūpono me ka hana ʻana o 1P, 2P, 3P, 4P, B-type, C-type, D-type, 18-module a 27-module, etc., aia ka laina hana i ka hoʻāʻo pūnaewele, maoli - ka nānā ʻana i ka manawa, ka ʻike ʻana i ka maikaʻi, ka bar code a i ʻole ka helu helu ʻelua-dimensional a me ka heluhelu ʻana, ka nānā ʻana i ke ola o nā ʻāpana, ka ʻōnaehana a me ka pūnaewele ʻōnaehana ERP, ke ʻano o ke ʻano hoʻohālikelike, ʻO ka nānā ʻana i ka ikehu akamai a me ka ʻōnaehana mālama mālama ikehu, nā lawelawe lako akamai, ka paepae ʻikepili nui a me nā hana ʻē aʻe, hana ʻia kēlā me kēia mīkini e Benny. Nā hana, ua hoʻolālā a hoʻomohala ʻia kēlā me kēia mīkini e Penlong Automation kūʻokoʻa, polokalamu polokalamu, hiki iā ʻoe ke hoʻomalu i ka hana ʻana o ka mīkini ma o ka pale hōʻikeʻike, loaʻa ka hemahema o ka mea ala, hōʻike hewa, ka nānā ʻana i ka ʻikepili hana huahana, ʻikepili OEE, etc. is conducive to lean production, troubleshooting, timely replenishment, etc., the operating system supports multi-language design. ʻO nā ʻāpana koʻikoʻi o nā mea hana mai nā mea kūʻai inoa kaulana honua e like me Kelemānia, Italia, Iapana, UK, USA, etc. Hiki ke kōkua i kāu hale hana e hoʻopakele i ka mana kanaka a me ka manawa, ʻike i ka automation hale hana a hopu i ka mahele mākeke no ʻoe.

1 、Ka uila komo lako lako: 380V±10%,50Hz;±1Hz;

5、ʻAha hui: hui manual, hui 'akomi hiki ke koho.

7 、 Nā lako me ka hoʻāla hewa, ka nānā ʻana i ke kaomi a me nā hana hōʻike ʻē aʻe.

9、Hoʻokomo ʻia nā ʻāpana kumu āpau mai nā ʻāina like ʻole a me nā ʻāina e like me Italia, Suedena, Kelemānia, Iapana, ʻAmelika Hui Pū ʻIa, Taiwan a pēlā aku.

10, hiki i nā mea hana ke koho "ka nānā ʻana i ka ikehu naʻauao a me ka ʻōnaehana mālama mālama ikehu" a me ka "lawelawe naʻauao lawelawe ʻikepili nui kapuaʻi kapuaʻi" a me nā hana ʻē aʻe.

11、Kuleana kūʻokoʻa kūʻokoʻa waiwai naʻauao